Custom plastic fabrication equipment can benefit companies in a wide array of industries. Construction companies can utilize this type of service to replace windows or operator protection features in their heavy equipment. Retail stores can use it to create completely original displays for showing off products or displaying unique signage. And energy companies can receive specially engineered plastic components to support their ever-changing equipment needs.

Since there’s such a huge variety of applications for custom plastic fabrication, there are also several different tools and pieces of machinery required to complete these jobs. Understanding the types of equipment involved in various fabrication and machining processes can help you ensure that you’re getting the best possible service from your own plastic fabrication vendor. Different jobs require different pieces of machinery, but nearly every fabricator should have access to these important items in order to create and customize the quality plastic materials you need to support your own operations.

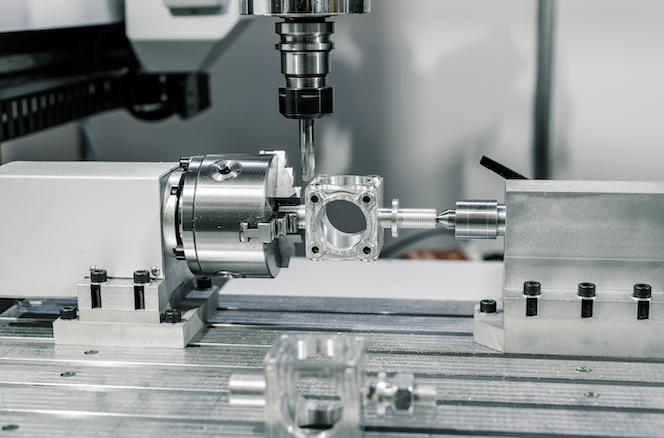

Custom Plastic Fabrication in CNC Machines

CNC machines are used to automate a variety of plastic customization processes. CNC stands for computer numerical control – basically, the machine can be programmed to move and process materials in a very specific way. But the idea is the same regardless of the exact change being made to the material — CNC machines are programmed to provide exact cuts or changes to a piece of material using software. Then the process of actually completing the fabrication is automated, rather than done by hand. This can help to eliminate errors and small variances, while also saving time and improving quality throughout the fabrication process.

In addition to their wide range of capabilities, CNC machines are also important for plastic fabricators because they provide repeatability. This provides customers with products that are consistent in size, thickness, material, and quality. For instance, a transportation company may need a set of windshields or replacement parts for a fleet of vehicles. The ability to get parts that are consistent across the entire fleet makes installation and quality control processes easier for that company later on.

Laser Cutters

Cutting plastic sheets and other components to size requires both precision and strength. Making cuts using traditional means can lead to unfinished edges or shapes that are less exact than what a specific project requires. With laser cutters, a very small and precise beam is used to interact with the material and cut or mark it. This provides a smooth finish and cuts that are completed to each project’s exact size and quality specifications.

This piece of equipment isn’t just important for cutting sheets or tubes to a specific size or length; laser cutters can also create very intricate cuts or designs into a wide array of plastic materials. This is a very beneficial option for companies that require components that don’t fit into standard shapes, like square sheets or tubes. With laser cutters, you still end up with fully finished edges and shapes that fit into your completed designs with precision.

Sanders and Polishers

From there, you need to worry about the finished surface of your custom fabricated plastic components. Sanders and polishers can help plastic fabricators create smooth edges and professional looking finishes over the outer shell of a completed plastic part or component.

More specifically, sanders can help to smooth rough edges after cuts or other changes to the material. It can also file down the surface to create a more even edge after a piece of plastic has been cut to size. Polishers can also be used to remove small chips, scratches, visual imperfections, or uneven edges along the surface. Overall, these processes and pieces of equipment can be used with a wide array of plastic materials and in a variety of different applications and finishes.

If you’re looking for a custom plastic fabrication vendor that has access to all the most important industry equipment, contact Polymershapes today. Using CNC machines, sanders, polishers, and more, our facility is able to offer a wide array of customized plastic products. Our Dayton fabrication center provides fabrication services for companies throughout the Midwest and East Coast, while maintaining ISO 9001 certification and ITAR compliance. With our state of the art machinery and years of industry experience, our team is well equipped to serve companies in a variety of industries, including construction, machining, energy, and retail. We’re also able to process requests quickly and deliver the custom plastic materials you need for a variety of projects within your company’s tight deadlines. If you’re ready to get started with your next plastic fabrication project, simply visit our website to request a free quote. A member of our team will get back to you within 24 hours so you can get the plastic materials you need as quickly as possible.