HIPS (High Impact Polystyrene), also known as PS (Polystyrene), is an amorphous thermoplastic material, used in lower heat applications. It is categorized as a standard material, and offers ease of processing, high impact strength, and stiffness.

Benefits of High Impact Polystyrene (HIPS)

High impact strength

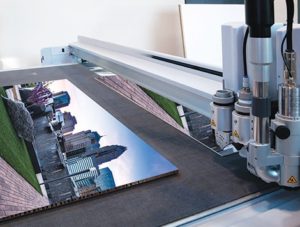

Can be printed using Digital, Screen, Flexo, and Litho inks

Fabricates well – can be guillotine cut, die-cut, punched and formed

Easy to Thermoform

Good dimensional stability

Fully recyclable with minimal loss of properties

FDA approved with 100% virgin resin

Technical Resources

- PVC vs CPVC: Which Is Better?

- Polypropylene vs. Polyethylene: How Do They Differ?

- Thermosets vs Thermoplastics: How They Differ

- Homopolymer vs Copolymer

- Plastics Pyramid

- Amorphous vs Semicrystalline

- Fiber Reinforced Panel Alternatives

- How To Choose the Right Plastic for Your Project

- LEXAN™ CLINIWALL™: Next Generation Wall Cladding

- BioPhorum, Polymershapes, and the Future of Material Sterilization

- Design for Manufacturability and Its Importance

- PETG – Markets Served and Industry Applications

Common Applications

Physical Properties

| Units | ASTM Test | High Impact Polystyrene | |

|---|---|---|---|

| Tensile strength @ break @ 73°F | psi | D638 | 2,480 – 4,520 psi |

| Flexural modulus @ 73°F | psi | D790 | 193,000 – 381,000 psi |

| Izod impact (notched) | ft-lbs/in of notch | D256 | 1.2 – 2.8 ft-lbs/in of notch |

| Water absorption @ 73°F – 24 hours | % | D570 | 0.036 – 0.11% |

| Coefficient of linear thermal expansion (CLTE) | (in/in F) | D696 | 5.0E-5 to 5.1E-5 (in/in/°F |

| Heat deflection temp. @ 264 psi | 160° – 189° F (71° – 87° C) | D648 | 160° – 189° F (71° – 87° C) |

* Technical Data is provided courtesy of UL Prospector (www.ulprospector.com) and IAPD (www.IAPD.org).

Data is to be considered representative and is provided for guidance only. All product performance must be verified by the user under actual application conditions.

POP/Display

POP/Display

Printing/Graphics

Printing/Graphics

Prototyping & Tooling

Prototyping & Tooling