In a rapidly changing environment, organizations and their employees need timely solutions, such as plastic face shields, that support their safety and wellness. Currently, the COVID-19 pandemic has left many businesses, health care facilities, and public service providers without sufficient protection. However, Polymershapes has recently begun offering a versatile solution that can help organizations ensure the protection, health, and wellness of healthcare employees and members of the general public.

In a rapidly changing environment, organizations and their employees need timely solutions, such as plastic face shields, that support their safety and wellness. Currently, the COVID-19 pandemic has left many businesses, health care facilities, and public service providers without sufficient protection. However, Polymershapes has recently begun offering a versatile solution that can help organizations ensure the protection, health, and wellness of healthcare employees and members of the general public.

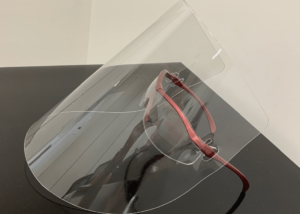

These new face shields are made of thin plastic sheets that create a physical barrier to protect individuals. They can be made using an array of materials and fabrication methods to fit the exact needs of end users. From ready to wear face shields that can be deployed quickly to adjustable face shields that work for various team members, this method of protection may help organizations searching for fast safety solutions for their team.

Since the COVID-19 pandemic is so new, sterilization effectiveness for these particular products is not yet known. However, plastics have the ability to create a physical barrier that may help organizations protect their workers and customers when paired with other safety measures. If you’re interested in learning more about plastic face shields and how they could benefit your operations, here’s a rundown of the options.

About Plastic Face Shields From Polymershapes

These thin-gauge clear plastics are ideal materials for protective face shields and other components that create a barrier between healthcare professionals or other essential workers and the public. Polymershapes can assist fabricators with solutions for every step of the production of their plastic face shields, and we offer a variety of materials that can be custom cut and converted for specific die-cutting or routing processes. Additionally, we can produce adjustable face shields, products that are able to fit over existing safety glasses, disposable shields, and even ready to wear face shields so organizations can improve their safety processes quickly.

Materials for Plastic Face Shields

Polymershapes also offers a wide array of options when it comes to plastics used in the production of protective face shields. Each of these options offer unique qualities and benefits that can suit various fabrication processes and end user needs. Here’s a basic rundown of the options.

LEXAN™ Polycarbonate

Polycarbonate is most known for providing excellent impact resistance, so it’s perfect for instances where plastic face shields need to be durable. This material also offers good visual clarity and scratch resistance. And finally, it’s lightweight and easy to fabricate, so it can work for fabricators that have very specific needs or processes that must be followed throughout the production process.

PETG

PETG offers good impact resistance, scratch resistance, and optical clarity. It’s also extremely easy to fabricate, so it’s perfect for plastic face shields that need to contour to a very specific shape or work with various customization processes. It’s also easy to clean and sanitize, offering a surface that may work for face shields that need to be used on multiple occasions.

PET

Finally, PET offers an option for plastic face shields that meets sufficient standards for impact resistance, scratch resistance, and optical clarity. The material is also easily fabricated and able to be cleaned and sanitized after use. However, it is also chemical resistant, making it ideal for end users that may need to encounter potentially hazardous materials while performing essential tasks.

If you’re interested in customizing plastic face shields for your operation, contact Polymershapes to get started today. We work with local distribution facilities around the country, so we can provide your team with personalized service and get materials out to you quickly. Reach out to our team to request a quote.