What should you look for in aluminum composite material suppliers?

Aluminum is a popular material for various applications. Plastics, though quite different from aluminum, also provide unique benefits for companies in a wide array of industries. Often, the qualities and capabilities of these materials make them well-suited for different use cases. However, they do sometimes overlap.

So what happens when companies or organizations want some of the qualities of plastics with the look and feel of aluminum? This is exactly the blend of qualities that aluminum composite material provides. Here’s a guide to this powerful option, its applications, and what qualities to look for in aluminum composite material suppliers.

What Are the Qualities of Aluminum Composite Material?

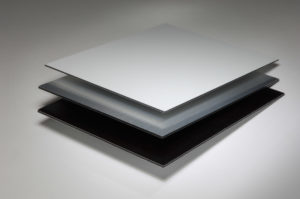

Aluminum Composite Material consists of two sheets of pre-finished aluminum that are bonded to a core of polyethylene plastic. This gives the rigid sheet of material the appearance and exterior strength of aluminum, with the lightweight and ease of use of polyethylene.

Some top benefits of aluminum composite material include the ability to easily cut, route, and form the material. So it can be completely customized to the aesthetic and practical needs of each application. It also provides a unique blend of qualities that combine the best elements of both metal and plastic. This allows users to enjoy the best of both worlds without committing all their resources to a single material category.

When compared to solid aluminum, ACM actually lays flatter and reduces oil canning and rippling effects, offering a more rigid and consistent appearance. In addition, ACM is more cost-effective and lightweight than solid aluminum produced in the same gauge and thickness. This makes it a more practical option both for companies on a budget and those that need to handle, alter, or install their own materials.

What Is Aluminum Composite Material Used For?

Aluminum composite material can be used in nearly any application where the look of aluminum but the lightness and cost efficiency of plastic may be beneficial. Most often, this involves creating indoor and/or outdoor signage, since aluminum provides a professional and finished-looking appearance, while polyethylene offers a solid, consistent core material. In addition, since ACM is easy to machine and cut or route into various shapes, it’s often used in three-dimensional letters or graphic elements for signs or displays.

Another use case for aluminum composite material is in the construction industry. ACM can be used as a replacement for steel or other metals in many applications that require just a flat sheet of material that isn’t load-bearing. For example, ACM can be used as an architectural face for a building exterior, or as an interior wall lining material. Since both aluminum and polyethylene offer some insulating properties, it can also be used in wall insulation.

These are just a few of the many applications that aluminum composite material suppliers can help with. If you’re looking for a material that combines the best qualities of metal and performance plastics, find an aluminum composite material supplier in your area and discuss how this option can work within your industry.

What Should I Look For in Aluminum Composite Material Suppliers?

Once you’ve decided to reap the benefits of aluminum composite material for your signage or construction projects, it’s time to find a reliable supplier that provides quality material options. Specifically, look for suppliers that offer top industry brands and have extensive experience in the plastics field. Some of the top brands and manufacturers in the ACM space include Dibond® and e-panel®, produced by 3A Composites.

Aluminum composite material can also be produced in a variety of colors, finishes, and thicknesses to truly customize the product to the needs of your project. For example, some users may prefer a glossy finish, while others opt for matte. There are also different grades ranging from heavy-duty to lightweight, depending on your size and durability needs.

Once you’ve chosen a material, quality aluminum composite material suppliers can also offer value-added services to further customize materials to your specific needs. For example, you may have sheets cut to size or in a particular shape to quickly print sign graphics on each face. A knowledgeable supplier that has experience working with companies in your industry can potentially point you in the right direction toward both the specific materials and customization options that best suit your industry requirements and project needs.

Turnaround times and customer service are the other main factors to consider when considering aluminum composite material suppliers. Time is of the essence when ordering materials for construction projects or new signage that supports your operations. A quality ACM supplier should provide quick quotes and have the materials in stock to suit your needs. This increases the likelihood of them having the necessary capacity to get materials to your location quickly. Fast service can be enhanced even further if you go with a supplier that has a location near you, since this can dramatically cut down on shipping and handling time.

If you’re looking for aluminum composite material suppliers that meet all the qualifications above, contact your nearest Polymershapes location. We offer ACM products in a wide array of colors, finishes, and thicknesses to give your company the ideal ACM sheets for your various applications. Our state-of-the-art facilities can also connect you with additional conversion, fabrication, and value-added services to further customize your materials. Visit our website to find your closest distribution center and reach out to our knowledgeable team members today.