Two of the most common commercial plastics in use today are polyethylene and polypropylene. Both are preferred materials across various industries, hailed for their lasting strength and various tolerances.

Both plastics are known as semi-crystalline materials. Semi-crystalline plastics have a highly organized molecular structure. Semi-crystalline plastics remain relatively unchanged across the temperature range below their melting point. However, once they reach their melting point, their transition into a liquid begins almost instantaneously.

They are both also classified as thermoplastics. Thermoplastics are polymers that can be melted and recast over and over again, retaining all of their core qualities. Plastics like polyethylene and polypropylene are not only easy to fabricate and cost-effective, but are also highly recyclable. Their ability to be melted down and recast makes both plastics easy to reuse, as opposed to continuously manufacturing new material.

Polyethylene and polypropylene are two of the most recognizable and widely used semi-crystalline thermoplastics. Despite their similarities, they each have unique characteristics that make them more suitable for different applications. Their chemical structure is a core part of what makes them such a common material.

What is a Polyolefin?

Polyolefins are a class of polymers formed through the combining of olefin monomers, also known as alkenes. Alkenes are hydrogen-carbon compounds with at least one carbon double bond. Once olefins/alkenes undergo polymerization, they link with one another to form a polyolefin. Polyolefins are known for being easy to make and can be combined with additives to alter properties/add new ones. Polyethylene and polypropylene plastics are among the most common polyolefins.

Polypropylene (PP)

Polypropylene (PP) is a semi-crystalline thermoplastic known for its toughness, chemical resistance, and low moisture absorption. The difference between polypropylene and polyethylene is that polypropylene offers a higher melting point. Polypropylene is also more chemically resistant, allowing it to operate in and around harsher environments.

Its high resistance to chemicals and solvents allows it to withstand various harsh sterilization techniques. Polyethylene is also chemically resistant, but polypropylene can tolerate a wider range of solvents, alkalis, and acids. Polypropylene can handle common rigorous sterilization techniques, most notably autoclaving and Ethylene oxidation (EtO). Its tolerance of rigorous sterilization techniques and harsh environments makes it useful in the healthcare sector, as well as chemical/drug development, pharmaceuticals, and more.

Polyethylene (PE)

Polyethylene is a polymer that is also classed as a semi-crystalline thermoplastic material. Just like polypropylene, it is a polyolefin. It is known for being one of the most widely used types of plastic in the world. It is a thermoplastic polymer that can be easily produced and modified, leading to a diverse selection of subtypes and grades. It is known for its combination of flexibility and durability. With other qualities such as tear resistance, electrical insulating properties, and chemical resistance, polyethylene has established itself as a reliable material for heavy-duty packaging.

Polyethylene’s popularity can be largely attributed to its chemical inertness paired with high strength, making it a highly versatile material.

The Many Different Types of Polyethylene

Some of the most common grades of polyethylene include:

- Low-Density Polyethylene (LDPE): Low-Density Polyethylene is known for its flexibility and strength despite its thinness. LDPE offers remarkable resistance to high temperatures, with certain grades capable of remaining stable up to 185°F (85°C).

- High-Density Polyethylene (HDPE): High-Density Polyethylene is a heavy-duty grade enhanced with durability and better chemical resistance. HDPE is known for resisting corrosion and absorbing very little moisture. It is most commonly used for packaging, food containers, bottles for chemicals, and more.

- Ultra-High Molecular Weight Polyethylene (UHMW): For further enhanced capabilities in demanding applications, UHMW features extremely high impact resistance. While this type of polyethylene is also commonly used in packaging facilities, it is often used inside the machines themselves.

- Polyethylene Terephthalate (PET): PET, also known as polyester, comes with many similar qualities to UHMW, but features a slightly higher melting point, enhanced dielectric properties, etc. It is also used for packaging and containers for various materials.

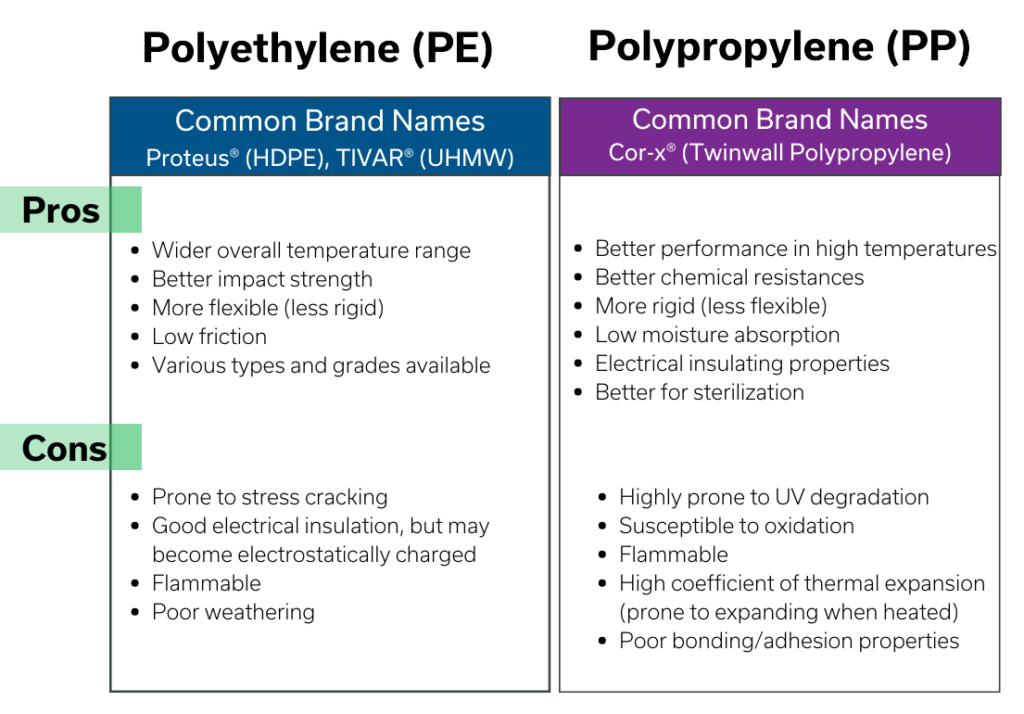

Polyethylene vs Polypropylene: A Summary

While both plastics are among the most widely used plastics across various industries, the differences between polyethylene and polypropylene could make one material better suited for certain applications than the other.