ABS is a type of plastic that is incredibly versatile and poised to see major growth in a number of relevant markets in the coming years. So it’s the perfect time for ABS plastic sheet companies and plastics fabricators around the country and the world to learn more about the factors that could impact this growing market.

Short for Acrylonitrile Butadiene Styrene, ABS is an opaque polymer and thermoplastic, which means it can be melted into a liquid and then cooled into a specific shape. It can even be reheated over and over again without significant degradation. These factors also make it easy to recycle and incredibly for a wide array of uses across industries, including several that could lead to major opportunities for plastic fabrication companies in the coming years.

If you’re interested in learning more about the growing market for this material and how it could impact ABS plastic sheet companies, read on for a guide.

Research Surrounding the Market for ABS Plastic Sheet Companies

Multiple research reports have been released in recent months that suggest the market for ABS plastic sheet companies is poised for growth. By understanding the trends and opportunities in the industry, ABS plastic sheet companies can be better equipped to position themselves for growth and success as well.

For example, research from Global Market Insights predicts that the market for ABS plastic sheets and similar materials will experience a 6 percent compound annual growth rate between 2016 and 2024. More specifically, the market size for ABS plastic in 2015 was $22.3 billion USD. And it’s predicted to grow up to $38 billion USD in 2024. It mainly cited several of the industries where ABS is commonly used and their potential impact on emerging markets in the coming years as the reason for this predicted growth. These include areas like construction, electronics, automotive, and appliances.

Additionally, a report from Grand View Research found that the plastics market as a whole is poised for consistent growth over the next several years, even with interruptions to several industries because of COVID-19. ABS currently holds a small section of the overall market for performance plastics, but it looks to be projected to grow on track with other plastics across industries, leading to significantly more opportunities.

Why the ABS Plastic Sheet Market Is Poised for Growth

ABS plastic is incredibly versatile and commonly used in several markets that are projected to see major growth in emerging markets over the next several years. Most notably, these include the electronics market, appliances, transportation, and construction.

Electronics companies often include ABS materials into their components because of its ability to insulate wiring and other components that produce heat. Obviously, as technology evolves, companies are continuing to produce a high number of hardware products in the U.S. and around the world. So any parts used in the production of these products are sure to be in high demand going forward.

ABS’s ability to hold up to both hot and cold temperatures also makes it popular in the production of appliances like microwaves, refrigerators, and washing machines. The market for this purchase in much of the world is remaining steady, while some developing countries and growing markets are seeing demand get significantly higher with growing population sizes and increasing urbanization.

In the automotive industry, manufacturers are constantly on the hunt for components and materials that are lightweight. ABS certainly fills this need, and it does so without compromising performance. More specifically, it’s often used when manufacturing vehicle interior panels, bumpers, and grills.

ABS is also commonly used in the construction industry, often for pipe and fitting needs. The construction industry is seeing tons of growth due to increasing urbanization rates in emerging markets, along with a general increase in construction spending worldwide. The construction industry has also generally been aiming to cut back on steel usage, and ABS provides a lightweight alternative in certain applications. It also offers an enhanced visual appearance and specific color choices to meet the aesthetic needs of end users.

Finally, ABS is also one of the plastic materials that is best suited for use in 3D printing. Since this emerging technology is poised to continue making a major impact on a wide array of industries, it’s certainly likely that this technology may contribute to growth for ABS sheet companies in the coming years. 3D printing can be used for everything from manufacturing small parts to product prototyping. As the technology improves and the equipment gets even more efficient, it’s likely that markets will continue to see high demand for plastic materials that can easily work with these processes and produce high quality end products.

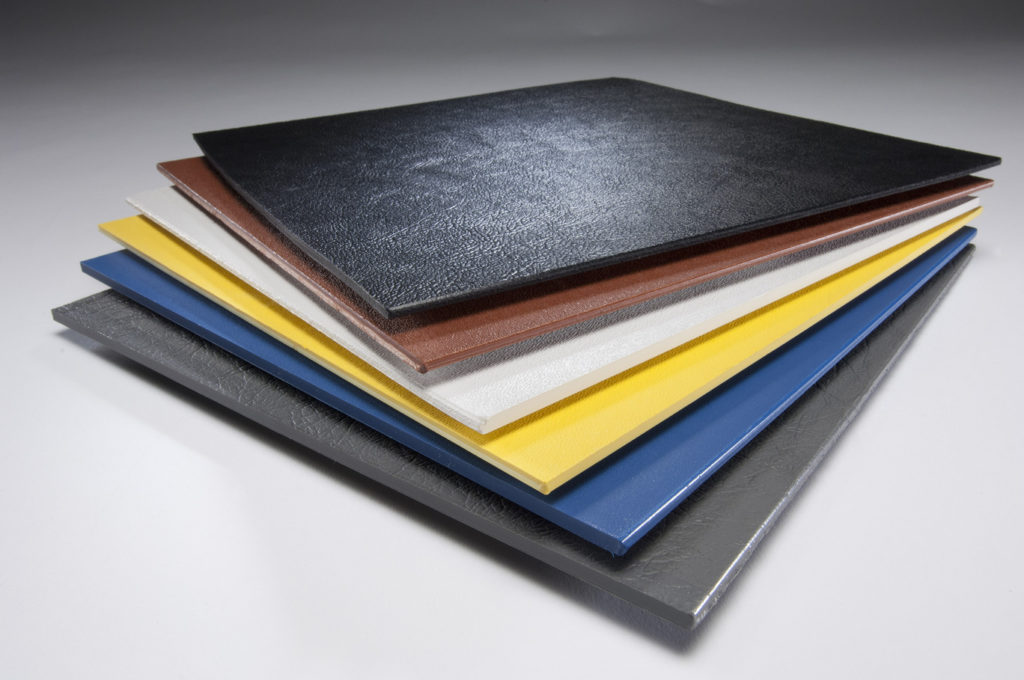

For ABS sheet companies that are ready to experience the growth potential in these emerging industries, Polymershapes can provide you with all the quality materials you need. We offer ABS sheets in an array of colors, sizes, and grades. And that’s not all; we also carry a huge selection of high performance plastics, including polycarbonate, acrylic, HDPE, nylon, and vinyl. We can fabricate materials to meet specific industry standards. And our distribution centers are conveniently located across the United States to give clients access to personalized service, fast quotes, and a seamless shipping process. Those same local facilities are also outfitted with industry leading equipment to ensure that all of our customers receive exceptional quality and customization options. Contact your local Polymershapes branch today to start reaping the benefits of the growing ABS market today.