There are a variety of reasons for using plastics - like PAI, ECTFE, PTFE, PEEK, PPSU, PVC-Acrylic, and much more - in aerospace applications, particularly airplanes. Plastics weigh less than metal, they don’t rust, they are easy to fabricate, there are many plastic materials that are fully Flame, Smoke, Toxicity and Heat Release compliant, and they offer a broad range of design flexibility in terms of color, texture, and pattern. Plastic parts can last longer and require less maintenance than other materials. One of the primary reasons for using plastic is the drive to eliminate weight from the plane, which improves cost by reducing fuel consumption. Contact us today for more information on plastics for Aerospace applications!

Plastics are used in many places both inside and outside the aircraft, including:

- Cargo Containers

- Dashboard Enclosures

- Cockpit Visors

- Dashboard Enclosures

- Radomes/Nose Cones

- Beverage Carts

- Counter Backsplashes

- Mirrors

- Toilets

- Ceiling and Wall Panels and Partitions

- Flooring

- Light Lenses

- Signage

- Video Bezels

- Various Seating Parts

- Window Reveals, Shades and Dust Panes

ECTFE (Ethylene Chlorotrifluoroethylene)

PPSU (Polyphenylsulfone)

PTFE (Polytetrafluoroethylene)

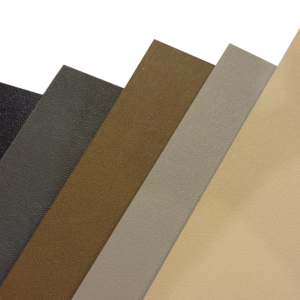

PVC-Acrylic

Silicone and Adhesives

PPS (Polyphenylene Sulfide)

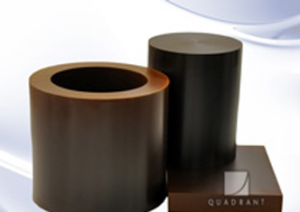

Phenolic/Thermoset Plastics

PI (Polyimide)

PAI (Polyamide-imide)

PEEK (Polyetheretherketone)

PEI (Polyetherimide, ULTEM™)

Composites & Processing Aids

HDU Board

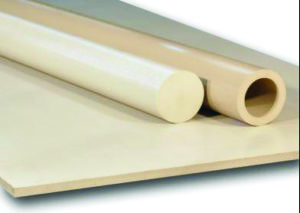

Nylon (Polyamide, PA)

Ultra High Molecular Weight Polyethylene (UHMW)

ABS/PVC

LEXAN™ Polycarbonate Sheets

Acetal (Polyoxymethylene, POM)