Plastic materials find use in a variety of applications in the food and beverage industry, particularly in processing and preparation. Most materials used in food and beverage processing will have to be certified as FDA, USDA, NSF, or 3-A Dairy. The use of clean-in-place (CIP), clean-out-of-place (COP), and sterilization-in-place (SIP) makes chemical resistance an important property of materials used in these applications. This gives plastics a significant advantage over metal. Higher machine speed demands also give plastics an edge over metal: they are lighter weight, enabling faster speeds with less energy usage. Machines that use plastic parts against metal, versus metal on metal parts, will be quieter at higher speeds, improving the working environment for operators.

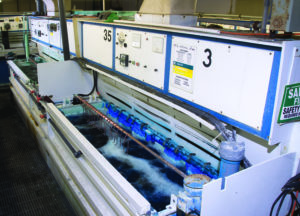

There are a wide variety of applications for plastics and plastic sheets within food and beverage preparation and processing. Plastic tubing is used for fluid handling. HDPE and Polypropylene can be used as cutting boards. UHMW is often used as wear strips on bottling and canning lines to enable higher machine speeds and longer Mean Time Between Repair (MTBR). Many conveyor components are made of plastics, including belts and roller wheels.

Plastics are used in many applications within food and beverage preparation and processing, including:

- Back Splashes, Trim, & Tables

- Bushings, Bearings, & Insulators

- Chain/Belt Guides & Guide Rails

- Conveyor Components, Wear Pads, & Wear Strips

- Cutting Boards

- Food & Beverage Filling Lines

- Funnels, Chutes, & Conveyors

- Gears, Sprockets, Pulleys, Rollers, Timing Screws, & Wheels

- Manifolds & Distributor Valves

- Nozzles

- Refrigerators/Coolers/Ice Machines & Liners

- Scraper Blades, Mixing Paddles, & Cams

- Seats, Seals, Rings, & Thrust Washers

- Various Food Molds

PVDF (Polyvinylidene Fluoride)

PTFE (Polytetrafluoroethylene)

Polyester (PET)

PEEK (Polyetheretherketone)

PEI (Polyetherimide, ULTEM™)

PETG (Polyethylene Terephthalate Glycol)

Nylon (Polyamide, PA)

Ultra High Molecular Weight Polyethylene (UHMW)

Industrial PVC/CPVC

ABS (Acrylonitrile Butadiene Styrene)

Interlocking PVC Panels

LEXAN™ Polycarbonate Sheets

Acetal (Polyoxymethylene, POM)

High Density Polyethylene (HDPE)

Polypropylene Sheet, Rod and Tube