Semiconductors and electronic devices require precision and stable environments in order to operate effectively. Because semiconductors control the flow of currents, it’s important to equip them with materials that can handle the heat and maintain control over electrical charges. Semiconductor plastics can help you meet industry needs. Low-outgassing and static dissipative grades are available to help reduce potential interference, enhancing the functionality of the equipment.

Polymershapes is a leading distributor and fabricator of the most in-demand low-outgassing plastics modern semiconductors use. Our large inventory of plastics has qualities that can reliably perform in and around electric fields, improving safety and stability. If you're looking the right high-performance plastic for semiconductors, professionals from Polymershapes can help.

Qualities of Semiconductor Plastics

- Lightweight

- Resistant to process chemicals/corrosive acids

- High temperature resistance

- Low outgassing characteristics

- Flame retardance

- Static dissipative

- Electrical insulating properties

Common Types of Plastic Used in the Semiconductor Industry

The most widely used types of semiconductor plastic solutions include:

- Acetal (Polyoxymethylene, POM)

- Polycarbonate (PC), LEXAN™

- Polyvinyl Chloride (PVC)

- High-Density Polyethylene (HDPE)

- Polypropylene (PP)

- Polyvinylidene Fluoride (PVDF)

- Polyetheretherketone (PEEK)

- Polytetrafluoroethylene (PTFE)

- Polyetherimide (PEI), ULTEM™

Acetal (Polyoxymethylene, POM)

Operating Temperatures: -40°F - 230°F (-40°C – 110°C)

Semiconductors and electronics often require tight tolerances to operate efficiently. Precision is crucial for semiconductor production, so it’s important to ensure the material that is selected is shaped to exact specifications. Acetal is an extremely durable material that can match the precision tight tolerance required.

Known for low moisture absorption, strength, and dimensional stability, acetal is very common because it helps maintain efficiency while also promoting workplace safety. Metals and other components could be conductive, increasing the risk of injury or failure. Acetal's low moisture absorption helps keep currents controlled and maintained. It also has great insulation properties. You'll find acetal used in chemical tank parts, electrical insulators, and more.

LEXAN™ Polycarbonate (PC)

Operating Temperatures: -4°F - 265°F (-20°C - 130°C)

Polycarbonate's strength and durability make it a go-to option for many applications. However, what makes it so common in semiconductors is its static dissipative capabilities. Semiconductors need a stable and highly controlled environment to function properly. Instead of allowing static to build up and cause disruptions, polycarbonate can help control and channel that static energy. Polycarbonate is also a low-outgassing plastic, allowing semiconductor devices to operate under the least amount of impurities possible.

Polycarbonate's anti-shock/static dissipative qualities and low outgassing rates make it an excellent material choice for test sprockets, valves, filtration material, tubing, and more.

Polyvinyl Chloride (PVC)

Operating Temperatures: 32°F - 140°F (0°C - 60°C)

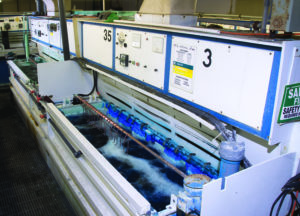

PVC sheets are a very common semiconductor material used throughout the assembly process. It features fire retardant, chemically resistant, and static dissipative grades that promote safety and purity from start to finish. PVC is the go-to material for wet processing systems, wet benches, workstations, robotic arm ends, chemical rinse tanks, and more.

High-Density Polyethylene (HDPE)

Operating Temperatures: -50°F - 180°F (-46°C - 82°C)

HDPE is a key material in the packaging and fabrication of semiconductors and electronics. Its chemical resistance and durability allow for chemicals and products to be transported or stored safely. HDPE can endure regular exposure to acids and solvents without degrading or reducing performance. It also has very low outgassing qualities. HDPE is commonly found in fabrication clean rooms and other vacuum-controlled spaces.

Polypropylene (PP)

Operating Temperatures: -4°F - 212°F (-20°C- 100°C)

Certain applications work with harsher acids or solvents and may require a material with a wider range of capabilities. Polypropylene shines in applications that need additional chemical, corrosion, and acid resistance. You'll commonly find PP being used in workstations, wet benches, integrated circuit chips, electrical insulators, carrier trays, and more.

High-Performance Semiconductor Plastics

Polyvinylidene Fluoride (PVDF)

Operating Temperatures: -4°F - 284°F (-20°C-140°C)

PVDF is a high-purity, high-performance plastic known for its temperature, chemical, UV, and abrasion resistances. What sets PVDF apart is its Izod impact resistance rating. It is known for its ability to sustain more blunt force trauma. Its excellent mechanical, electrical, and chemical properties make it an essential material in semiconductor manufacturing. Lastly, it is known for being a long-term investment, providing consistent performance for decades.

PVDF is commonly used as chemical tank liners, high and ultra-high purity process piping, semiconductor equipment components, semiconductor sensors and membranes, and more.

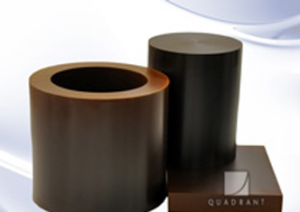

Polyetheretherketone (PEEK)

Operating Temperatures: -94°F - 480°F (-70°C - 250°C)

PEEK is a semi-crystalline, high-performance plastic that is known for its wide temperature range and compatibility with water-based applications. Even though PVDF has a higher Izod impact rating, PEEK has a broader operating temperature range and better mechanical properties. PEEK also features low outgassing and doesn't undergo hydrolysis, meaning it can perform in applications that require long-term exposure to water or steam.

PEEK is commonly used in wafer-processing applications, gas delivery systems, structural components in electrical devices, integrated circuit test sockets, and more.

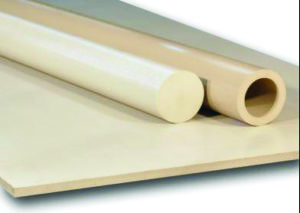

Polytetrafluoroethylene (PTFE)

Operating Temperatures: -328°F - 450°F (-200°C - 232°C)

PTFE is a high-performance, semi-crystalline insulating material known for its very high breakdown voltage threshold. With a dielectric constant of around 2.1, it can operate under high voltage without breaking down due to electrical charge. Due to its chemical inertness, PTFE is not a good charge carrier. Its low electrical conductivity and chemical inertness allow it to aid in keeping electrons stable as they flow through a current.

PTFE is often used as valves, seals, bearings, chemical processing equipment, wire insulation, and more.

ULTEM™ Polyetherimide (PEI)

Operating Temperatures: -454°F - 420°F (-270°C - 215°C)

Polyetherimide, otherwise known as ULTEM™, is an amorphous thermoplastic known for its extreme temperature range and outstanding dimensional stability. When paired with its chemical resistances and sustainability, PEI is revered as one of the most reliable semiconductor plastics available. ULTEM™ is often used a replacement for metal in high-performance machinery, semiconductor process components, underwater connector bodies, electrical insulators, and more.

Common Applications for Semiconductor Plastic

- Test sprockets

- Valves

- Seals

- Bearings

- Circuit boards

- Chip carriers

- Robotic arm ends

- Chemical rinse tanks

- High purity piping systems

- Gas delivery systems

- Semiconductor trays & boxes

- Electrical insulators

- Wafer handling parts

- Wet benches & workstations

- Flexible tubing

Learn More About Polymershapes' Semiconductor Plastic Materials

Polymershapes is one of North America's leading distributors of the most reliable plastic materials needed for semiconductors. From low outgassing materials to static dissipative grades, our distribution centers have a wide selection of material options from the most reputable brands. To invest in semiconductor plastic materials, contact a Polymershapes professional today.

ECTFE (Ethylene Chlorotrifluoroethylene)

PVDF (Polyvinylidene Fluoride)

PPS (Polyphenylene Sulfide)

Phenolic/Thermoset Plastics

PI (Polyimide)

PAI (Polyamide-imide)

PEEK (Polyetheretherketone)

PEI (Polyetherimide, ULTEM™)

Ultra High Molecular Weight Polyethylene (UHMW)

Industrial PVC/CPVC

ABS (Acrylonitrile Butadiene Styrene)

Acetal (Polyoxymethylene, POM)

High Density Polyethylene (HDPE)