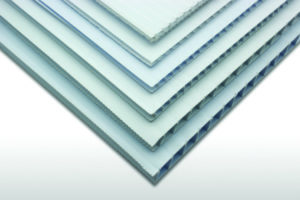

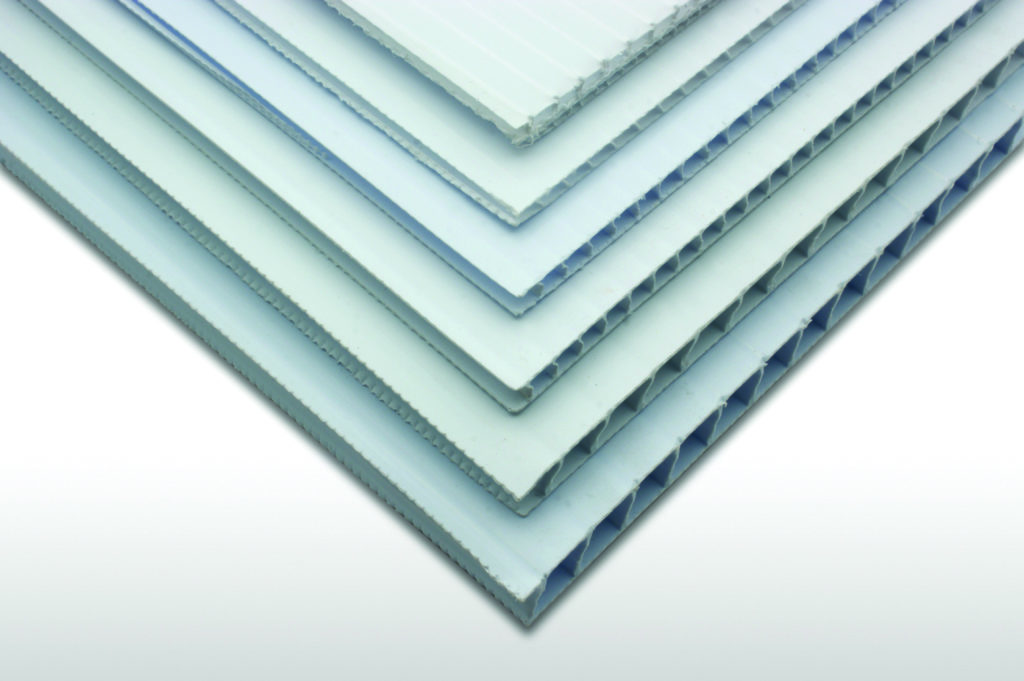

Corrugated twinwall is a plastic material that goes by many names, including fluted polypropylene, Coroplast®, Cor-X®, and polypropylene twinwall. The material consists of two thin sheets of polypropylene plastic that are connected by a layer of that same material arranged in a ribbed pattern. This makes it basically look like cardboard, but with a glossy plastic finish instead. It’s an incredibly versatile material that can be used in many different applications.

If you’re in the market for corrugated twinwall or want to learn more about what the material can bring to your company’s projects, here’s a guide to its attributes and applications.

Attributes of Corrugated Twinwall

Corrugated twinwall is a very economical material. So it can help companies keep their plastic related projects under budget. Whether you’re purchasing materials for product creation, marketing, or packaging, it’s likely to be one of the more affordable options on the market. It’s inexpensive to purchase whether you’re looking for a large amount of sheets or just a few.

Additionally, it’s easy to fabricate, print, and install. Plastic fabrication companies can produce and fabricate the material fairly quickly, which means lower costs and faster order delivery. It also means it can be produced in tons of different sizes and with other customization options. Since corrugated twinwall is often used for signs and displays, easy printing is a must. But since the material is light and smooth, people are able to print all different kinds of messages, graphics, and color combinations on them. And installation is seamless once the material is produced. So there’s not any major learning curve that buyers need to be aware of.

The material is also incredibly lightweight. This makes it easy to ship, transport, and work with. Even if you need to order a large selection of these sheets for signs or other purposes, you should be able to get them fairly quickly and without much hassle. And once you receive them, distribution is likely to be relatively seamless.

Once corrugated twinwall plastic is put to use, it is able to hold up well in a variety of conditions. It’s durable and water resistant, which makes it especially well suited for outdoor signage and displays. Of course, it can also be installed indoors, in which case it can last even longer. But when used in an outdoor setting, the material’s ability to resist damage from water, UV rays, and other extreme conditions can help it to last for as long as needed. And these signs or displays don’t lose their form or fade significantly, so they can continue to share important messaging throughout long election or promotion seasons.

Applications of Corrugated Twinwall

Perhaps the most common use of corrugated twinwall plastic is in signage. You likely see it in yard signs throughout election season. But it can also be used in storefront signs for small businesses or yard signs that promote small home services businesses like house painters and landscapers. It’s well suited for this purpose because it’s so durable, weather resistant, and lightweight. It can hold up well to the elements for a significant period of time. And it’s easy for businesses, organizations, and campaigns to distribute signs to relevant households or locations. It can also be used indoors, in which case it can last for an even longer period of time.

Additionally, some businesses use corrugated twinwall in the creation of retail displays. It’s sturdy enough to be used to hold and display small products. And since it can be printed easily, it’s perfect for calling attention to sales or new items that have recently launched. Companies can have information about products or branding design elements added to each panel. Its durability and low weight also makes it perfect for use at trade shows and special events, because sellers can easily transport it and set it up without worrying about excess weight or potential damage.

Some home improvement contractors may also use corrugated twinwall in various building or construction projects. For example, they can lay it down as a temporary floor to prevent messes and damage on subfloors. And they can easily hold up sheets and cut them to size to find the exact measurements needed for new structures like kitchen or bathroom countertops. It’s perfectly suited for these temporary solutions because of its low cost and ease of use.

Finally, some companies have begun using corrugated twinwall plastics in eco-friendly packaging solutions. The material can hold up against wear and tear during the shipping process and even resist water damage. It’s lightweight and sturdy enough to make transport and handling easy. But it can also be reused, meaning it’s a more sustainable solution than many disposable packaging systems. In some cases, it may even be able to help companies save money in the long run if they’re able to use boxes and containers more than once instead of constantly producing or ordering other packaging or shipping materials.

If you’re looking for corrugated twinwall for signage, packaging, or any other applications, Polymershapes can help. In addition to corrugated twinwall, we provide a wide array of performance plastic solutions, from polycarbonate and acrylic to ABS and HDPE. Our local distribution centers are conveniently spread throughout the country to offer convenient and fast service. Those facilities are also outfitted with industry leading fabrication equipment to offer a wide range of customization options. Basically, clients get the best of both worlds: the convenience and service of a local operation and the quality and capabilities of a nationwide brand. Contact your local Polymershapes branch today to start reaping the benefits of corrugated twinwall.