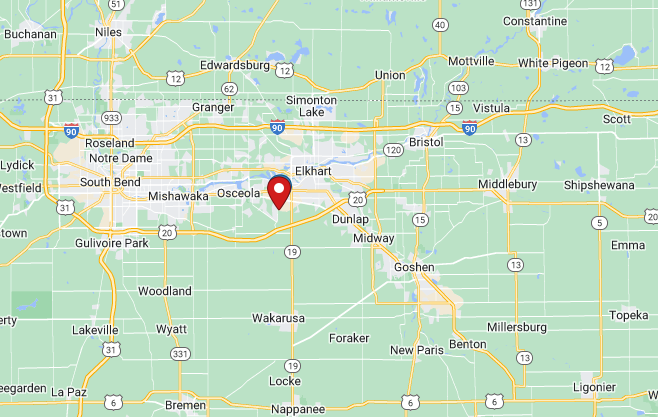

Polymershapes offers a wide range of bus and rail plastic materials to meet the industry’s unique demands. Whether meeting strict flame and toxicity requirements or looking for improved aesthetics and design freedom, plastics offer a lightweight solution with impact, abrasion, and chemical resistance. Our Elkhart, Indiana, location is ready to assist your bus and rail needs.

Materials That Meet the Highest Standards

UL 94 V-0 | ASTM E-162 | ASTM E-662

ANSI Z26.1-1996 | FTA, UMTA & Docket 90A Guidelines

Clear Plastic Solutions for Bus & Rail

With an increased focus on safety, sustainability, and compliance, clear performance plastic materials are bringing innovation to the Bus & Rail industry. When compared to glass, materials such as polycarbonate and impact modified acrylic can significantly lower system costs by consolidating parts to streamline production, avoiding secondary operations such as machining and polishing, reducing maintenance, downtime, and replacement costs, while reducing weight and increasing vehicular efficiency.

Common Applications

- Shelters

- Dividers

- Driver Enclosures

- Replacement Glazing (Fritted & Non-Fritted)

Common Materials

Polycarbonate

Commonly known as LEXAN™ or MARGARD™

- Virtually unbreakable

- Crystal-clear transparency

- Lightweight compared to glass

- Excellent formability

- Anti-fog, UV resistant, abrasion resistant

- Anti-vandalism grades available

Impact Modified Acrylic

Commonly known as Duraplex™

- Stronger than standard acrylic

- Superior, optically clear transparency

- Lightweight compared to glass

- Excellent weatherability

- Easy to thermoform with no drying

- Available in clear and tints

Engineered Plastic Solutions for Bus & Rail

Compared to metals, plastics are lightweight, corrosion-resistant, and easy to fabricate. When replacing metal, materials such as Acetal, UHMW, and Nylon offer superior abrasion and impact resistance, as well as excellent strength and stiffness.

Common Applications

- Wear Plates

- Impact Plates

- Rollers

- Sliders

- Bezels

- Gears

Common Materials

ABS

Acrylonitrile Butadiene Styrene

- Outstanding impact strength

- Easy thermoforming

- Exceptional machinability

- Excellent chemical resistance

Acetal

Commonly known as Acetron® or Delrin®

- High strength and stiffness

- Enhanced dimensional stability

- Easy to machine

- Low friction

Nylon

Commonly known as Nylatron®

- Balance of strength and toughness

- Good wear, impact & abrasion resistance

- Good mechanical and electrical characteristics

- Reduced noise, weight and wear of mating parts

UHMW-PE

Commonly known as TIVAR®

- Outstanding abrasion resistance

- Impact resistance

- Chemical resistance

- Low coefficient of friction

For more information on bus and rail applications: https://www.polymershapes.com/application/bus-and-rail/