If you use any custom plastic parts for your company’s displays or operations, quality CNC machining and fabrication is a must. This is what allows companies to access custom parts that fit their existing equipment or meet specific industry criteria.

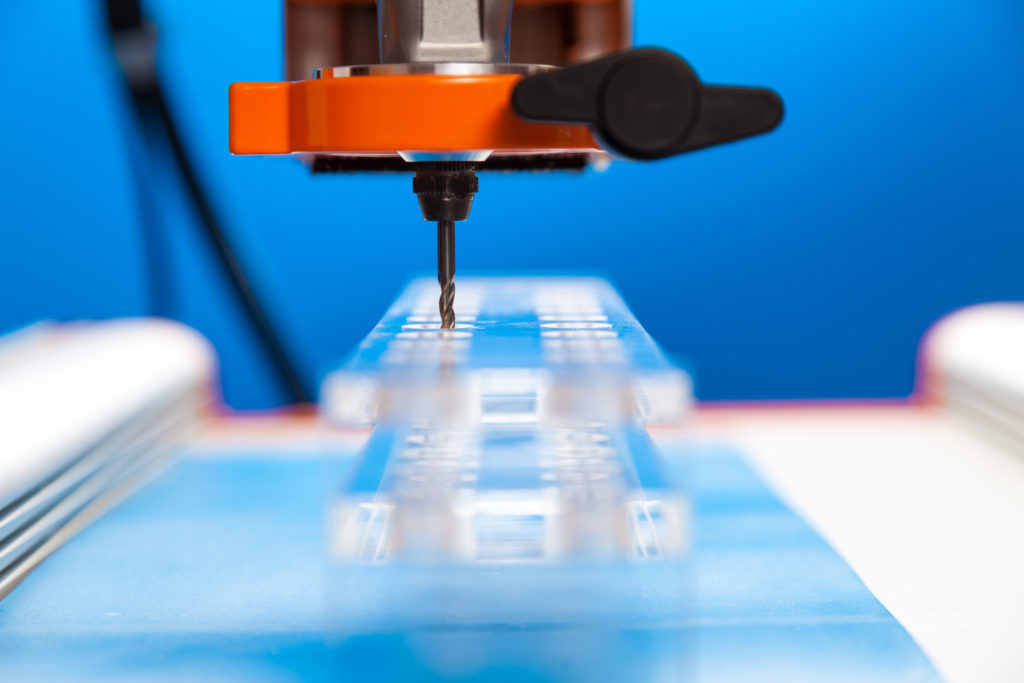

CNC machining and fabrication is an essential process for cutting and forming raw plastic material into the specific parts needed to complete a project. The process uses CNC routers and machines, which are some of the most popular and necessary pieces of plastic fabrication equipment available today. However, not all plastic fabricators that offer CNC machining and fabrication provide the same level of quality and efficiency.

If you really want to make the most of your customized plastics, computer aided design and automation tools can be a major benefit. CNC machining and fabrication with AutoCAD allows companies to enjoy more precise customizations, fewer errors, and optimal turnaround times. For those who are interested in taking advantage of this technology or who want to learn more about the options available, here’s a guide to AutoCAD and its potential impact on CNC machining and fabrication.

What AutoCAD Does

AutoCAD is a powerful computer-aided design software program. It can be used to create a wide array of drawings, models, or construction setups, including both two-dimensional and three-dimensional designs. Basically, it makes it easy to create specific designs and visualizations without having to draw everything out manually. Then each design can be saved and used in fabrication plans or stored for later use.

With AutoCAD, you can create and view designs in a realistic setting. It allows you to draw to a specific scale, set standards that each design must include, create dimensions, adjust designs over time as needed, and store everything in an easily accessible digital program. Essentially, it digitizes the process of creating drawings and designs that can later be used in plastic fabrication or other physical product production.

How It Benefits CNC Machining and Fabrication for Plastics

In short, AutoCAD makes it easy for plastic fabricators to get the best possible performance from their CNC machining and fabrication tools. The ability to carefully create designs with the help of a computer and then automate the process of fabricating and machining plastics to those exact specifications can help companies save time, improve part quality, and avoid costly errors and downtime.

Now more than ever, plastic fabricators are under pressure to produce parts with increasingly complex designs. Creating those visuals and controlling machines manually can take a ton of time, expertise, and focus. Plastic fabricators can spend a ton of extra working hours controlling every single aspect of the process. However, investing in the right tools from the start can mean that each project is significantly less time consuming, which leads to increased productivity and efficiency for plastic machining and fabrication teams and faster turnaround times and more reasonable prices for consumers.

Additionally, using computer aided design programs to create visuals and adjust as needed means improved accuracy and precision for every project. Completing plastic machining and fabrication projects using manual processes can lead to small errors, inconsistencies, or mistakes that ultimately impact the quality of the end product. AutoCAD allows you to create incredibly precise drawings that you can adapt to your specific needs, whether you’re working on two-dimensional or three-dimensional scales. So there’s less room for errors and improved quality and consistency throughout. Additionally, it’s easy to adjust designs in this type of program, so if an initial design doesn’t come out as intended, you can make small changes quickly and easily rather than starting from square one.

Not only does this result in higher quality plastic products, but it also means less downtime and less waste for companies that utilize custom plastics in their operations. For example, if a manufacturing company is waiting for a specific part that needs to be fabricated using a CNC machine, it’s probably important that the part in question arrives as quickly as possible and without any errors. If something is wrong and the part needs to be redesigned or fabricated again, that means more time is wasted where the machinery in question cannot be used. It likely also means wasted materials and money. Luckily, using computer aided design and automation can dramatically cut down on these small issues and ensure that everyone involved in the process gets the exact items they need as quickly as possible.

If you’re looking for a CNC machining and fabrication company to provide quality plastic materials and efficient service, look no further than Polymershapes. We use the latest technology to turn your drawings into custom machined parts and fulfill your company’s specs to exact precision. Our custom plastic products are perfectly suited to meet the needs of companies across a wide array of industries, including transportation providers, government organizations, healthcare facilities, energy providers, and industrial plants. We work with top suppliers to provide the highest quality materials available, and we also offer expert conversion capabilities like cut-to-size sheets, film conversion, and CNC routing to ensure that the finished products always meet your organization’s specs. In fact, our Dayton fabrication center is equipped with four CNC routers and three CNC mills that use high quality software to ensure accuracy and precision for each order. To discuss your organization’s plastic needs or CNC machining and fabrication, visit us online to request a quote today and a member of our team will get back to you within 24 hours.