Today’s contractors have access to a huge array of materials to suit various needs for clients. Whether you work with residential, commercial, industrial, or even government facilities, there’s a good chance you may encounter LEXAN™ plastic sheets during jobs. This material offers a ton of benefits for various applications, so it is becoming increasingly popular among contractors and their clients.

Whether you’re encountering LEXAN plastic sheets for the first time or just looking for ways to improve your current processes while working with this powerful material, here’s a guide to this option specifically for contractors.

What Are LEXAN Plastic Sheets?

LEXAN plastic sheets are made from polycarbonate, an incredibly strong plastic material that is about 250 times more impact resistant than glass. LEXAN is actually a trademarked name by SABIC. But it has become somewhat synonymous with clear polycarbonate sheets, so the two terms are often used interchangeably. You may also hear it called LEXAN glass, though it doesn’t actually contain any glass. Many forms of bullet-resistant glass are also produced using this material, though it’s sometimes combined with actual glass, laminate, or other materials as well.

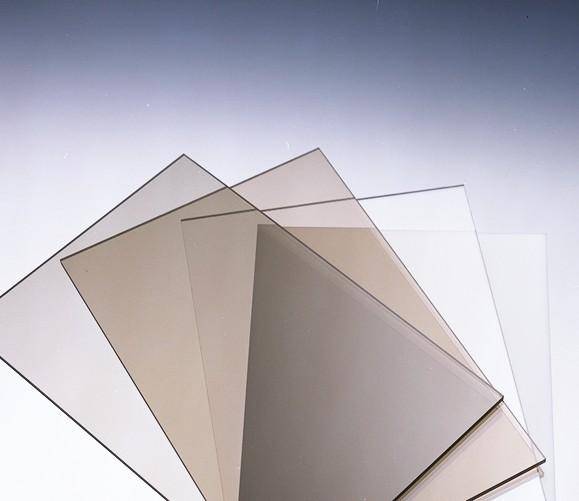

LEXAN plastic material mainly comes in clear sheets, which can be produced in a variety of different grades and gauges. Sheet thicknesses range from 0.03” to 0.5”, and some popular grades include machine grade, graphic, flame retardant, FDA, abrasion resistant, and general purpose. Most LEXAN plastic sheets are clear, but they can also come in white, gray, or bronze finishes depending on the aesthetic preferences and needs of the end user.

Benefits of LEXAN Plastic Sheets

LEXAN plastic sheets are often chosen for various applications due to their impact resistance. This material makes an ideal replacement for glass in applications where the material may be struck by debris or where extra safety and security considerations are necessary. However, there are additional benefits that apply mainly in the construction field where contractors are likely to encounter it.

For example, polycarbonate is generally much lighter than glass, so it’s easier to handle, transport, and install. Though contractors should still use care while handling polycarbonate around work sites, it is unlikely to break or shatter if someone accidentally drops or mishandles it. This means less dangerous debris and decreased material waste on various projects.

LEXAN plastic sheets can also be bent and shaped using targeted heat. This can sometimes be completed by a plastics fabrication service, so contractors can simply receive the materials they need ready for use and/or installation. However, some use their own heat coils or air circulators to heat these sheets and shape them on site. Overall, it’s a quite versatile material that can be customized to the specific needs and preferences of building owners or developers. So the ability for contractors to work confidently with LEXAN plastic sheets may lead to increased client satisfaction over time.

Applications of LEXAN Plastic Sheets

LEXAN plastic sheets are used across industries. However, contractors are most likely to encounter this material in construction-related applications. In these settings, LEXAN plastic sheets are generally used in place of glass. For example, they may serve as windows, skylights, door inserts, clear partitions, safety barriers, and greenhouse exteriors.

They can also be used in areas where extra security may be necessary, since polycarbonate is able to absorb the energy from impact without breaking or spalling. For example, commercial contractors may install these sheets over countertop areas at banks, convenience stores, or government facilities.

Tips for Contractors

Before even starting a project that utilizes LEXAN plastic sheets, be sure you understand exactly what the material will be used for and what type of environment it is going to be exposed to. This can help you choose the right style and grade so it can stand the test of time and avoid unnecessary damage and wear. For example, sheets used in safety barriers may require special capabilities like fire resistance or UL safety certification.

Though polycarbonate can be cut and formed, it is most efficient for contractors to order cut-to-size products. This allows you to receive items that are ready for installation at your work site. It also prevents the need to purchase specialized cutting equipment, since the material is too strong to cut using normal tools. Allowing a trusted plastics supplier to do the cutting for you also eliminates material waste, cuts down on extra steps, and can keep project costs under control.

Though LEXAN is incredibly strong, it is possible for them to get damaged or deformed in certain environments. Specifically, avoid exposing the material to any sharp objects, as the material’s surface can get scratched. You should also avoid exposing it to extreme heat, since thermoplastics can bend once they reach their melting point. Some contractors do use heat tools intentionally but avoid excessive heat exposure in other instances.

If you’re looking for quality LEXAN plastic sheets for any upcoming projects, Polymershapes can help. We offer LEXAN products in an array of gauges, grades, and finishes to suit each type of project. Our knowledgeable team can even help contractors select the right materials and value-added services to suit each particular need. From there, our local fabrication centers ship materials quickly and provide quality service every step of the way. To get started, simply visit our website to find your nearest location.