One important element of selecting a plastics provider is ensuring they provide the plastic cutting services and customization options needed to truly optimize your operations. Plastic sheets, rods, and tubes often come in stock sizes.

However, these full-sized products are rarely ready for use in their most basic forms. A plastic cutting service can help you get the precise materials needed for each project & industry use case in a much more usable form.

If your company uses plastics for various applications or operational needs, here’s why a plastic cutting service with vast industry knowledge can dramatically improve your company’s productivity and success.

Capabilities of a Plastic Cutting Service

A plastic cutting service customizes raw plastic materials to the specific size and dimensions needed for specific products. There are various tools and methods used to achieve this end goal. Your plastic cutting service should be well positioned to help you understand the options more in-depth and choose the value-added services that are right for you. But in the meantime, here are some specific fabrication methods you may look for:

- Cut-to-size sheets: This basic service trims edges from flat sheets to produce the exact dimensions needed for a specific project. This can be completed for single sheets or at scale. Edge finishing services can produce a smooth finish along each cut.

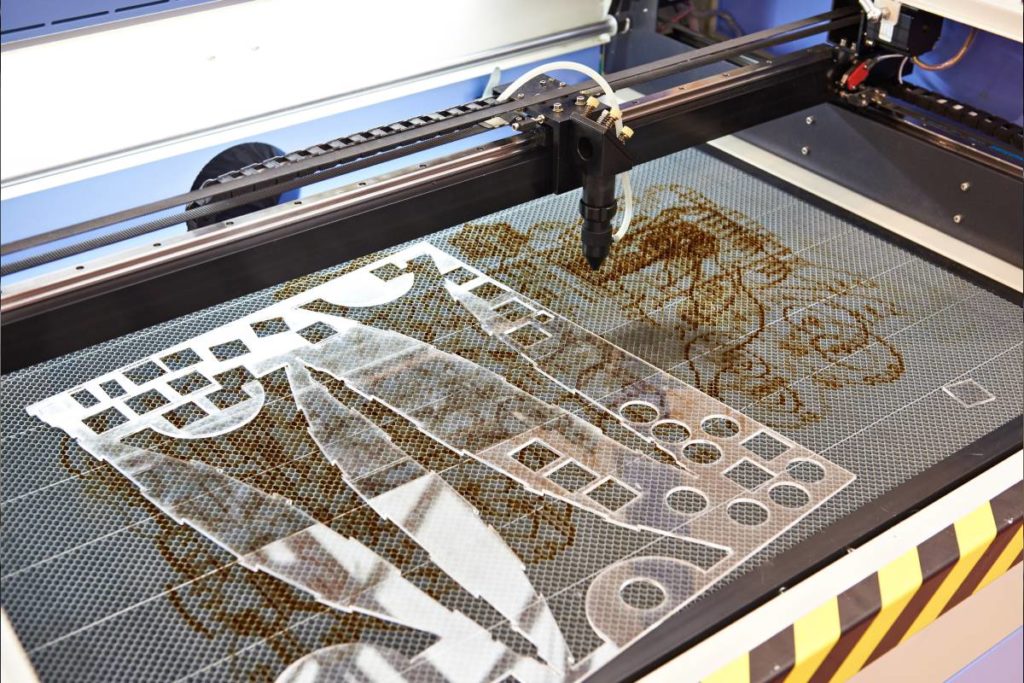

- CNC routing: CNC routing uses digital designs to cut specific shapes into each piece of raw plastic material.

- Reel Cutting: Reel cutting trims thin plastic sheets straight from master reels. Materials are available in a variety of gauges, and the finished materials can ship either as flat pieces or rolls.

- Cut-to-Size Plastic Rods: If your project requires rods rather than flat sheets, you can select the width that works best for your application and have the length trimmed to suit your needs.

- Film Sheeting: If your project requires film, you can have rolls of film trimmed and squared on a guillotine so each piece is ready for use. Film sheets are then carefully wrapped and packaged for shipping.

- Trimmed and Squared Plastic Sheets: This method involves creating guillotine cuts on all four sides of each material. This method is especially popular with strong materials like acrylic, polycarbonate, and PETG.

- Film Slitting: This method cuts master rolls of film down to smaller rolls that are narrower in width and/or shorter in length, so you can then use the roll without cutting each piece on multiple sides.

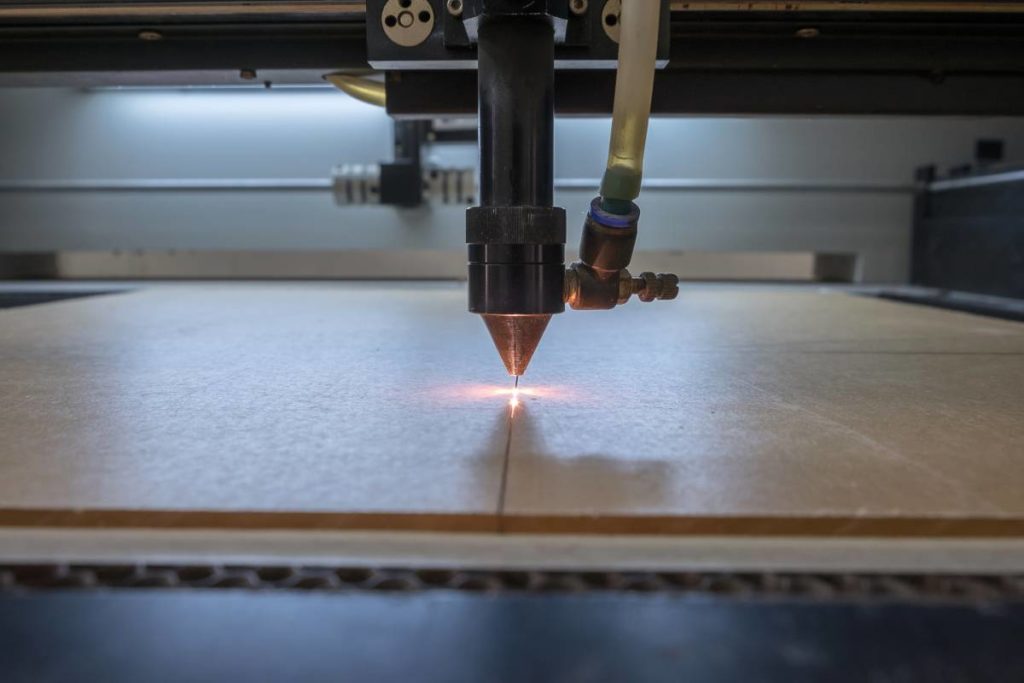

- Laser cutting: This method creates a clean, finished edge and provides tight tolerances for precise applications.

Benefits of Working With a Plastic Cutting Service

Stock plastic materials still offer a ton of high-performance properties. But most firms need materials that suit the specific size requirements of each project. A plastic cutting service ensures that you receive these materials ready to use, rather than needing to invest in your own fabrication equipment or look around for third-party service providers after receiving the raw materials.

This extra service offering can dramatically improve your team’s productivity and lower costs for each project. Plastic cutting and fabrication requires specialized knowledge and powerful equipment, so it’s not always possible or practical for companies to handle these customization services on their own. And today’s businesses need materials quickly. A plastic cutting service reduces the amount of time needed to customize materials and ensures your products arrive quickly and ready for use in your precise applications.

Why Working With a Plastics Expert Is Beneficial

Selecting a plastic cutting service isn’t just about looking for high-powered fabrication equipment. It’s also beneficial to partner with an expert in the plastics industry that also has experience working with companies in your field.

Experienced plastic cutting services are more likely to have the knowledge, expertise, and equipment necessary to provide the customization services that are most relevant for your needs. Companies that use performance plastic materials don’t always know the specific options available and the pros and cons of each. So a plastics expert can walk you through the processes and make suggestions based on their understanding of your project and overall goals.

This is why it’s also beneficial to work with a plastics expert that has experience with your particular industry. If they’ve worked on similar projects in the past, they may know the exact cutting and fabrication options that other firms have had the most success with. So they can make suggestions and speak knowledgeably about relevant industry regulations and performance requirements.

If you’re ready to bring efficiency to your operation with a plastic cutting service, contact Polymershapes for all your customization needs. We offer a huge array of cut-to-size products, including plastic sheets, rods, and even film conversion services. We can cut one sheet or several hundred, depending on the needs of your projects. Our quality machinery and vast industry knowledge allow us to provide materials cut to your exact specifications, with tight tolerances and edge finishing services also available. Our local facilities spread throughout the U.S. have access to a huge inventory of high-quality plastic materials from top manufacturers. So we can suit the needs of companies in a huge array of industries. Visit our website to find your local supplier and plastic cutting service to get started today.