Similar to PVC-Acrylic and Polycarbonate, PETG is impact-resistant, durable at high temperatures, and versatile for virtually any market. Commonly transparent but colorable, it can be formed into virtually any custom shape, and also has the benefit of being FDA-approved for use in food-safe applications such as plastic packaging. Here’s more information about a few of the use cases where PETG is a frequently used plastic material.

PETG for Display and Retail

Signage and display cases are another area where PETG plastic material excels. The capability of including printing, logos, and visual elements creates an ideal product for viewability in public spaces. It also can be created to exhibit a transparent effect. Combined with an impact resistance quality, this product serves well in these commercial applications.

PETG also exhibits a physical lightness of weight that combines well with its hardiness. It can be cut, shaped or printed with virtually any size or form. While not well suited for ultraviolet exposure or being wet, it’s perfect for store retail signs or similar situations where a glass substitute is needed as well as a custom-cut option that is physically robust for a number of product design applications.

Food Industry

The FDA regulates requirements around comestibles packaging, and PETG is used in packaging for food distribution. This material meets all toxicity regulations for coming into contact with food and beverages. As a result, this material is a perfect choice for these applications where health and safety are paramount, without sacrificing durability.

Additionally, PETG is both chemically resistant and can be crafted with clear transparency, and also maintains its strength and form even during substantial movement during shipping. It’s also heat resistant and works well not just with packaging but also food handling equipment and other materials during food processing and the packing process. With ease of fabrication, printing, and a high degree of integrity during transit, PETG is perfect for food and beverage industry applications.

Manufacturing and Industrial PETG, Machine Guards

Among the many uses of PETG, in a manufacturing or industrial focus this material is often used for machine guards, equipment and personnel protection. The inclusion of safety features or shields to protect either life and limb or machinery components from sparks, spall or chips is well suited by this plastic material. While not as durable as some products such as Polycarbonate, it’s still known for its impact-resistant strength and protective qualities. PETG also has the benefit of being temperature-resistant, and can withstand relatively higher heat without losing its form.

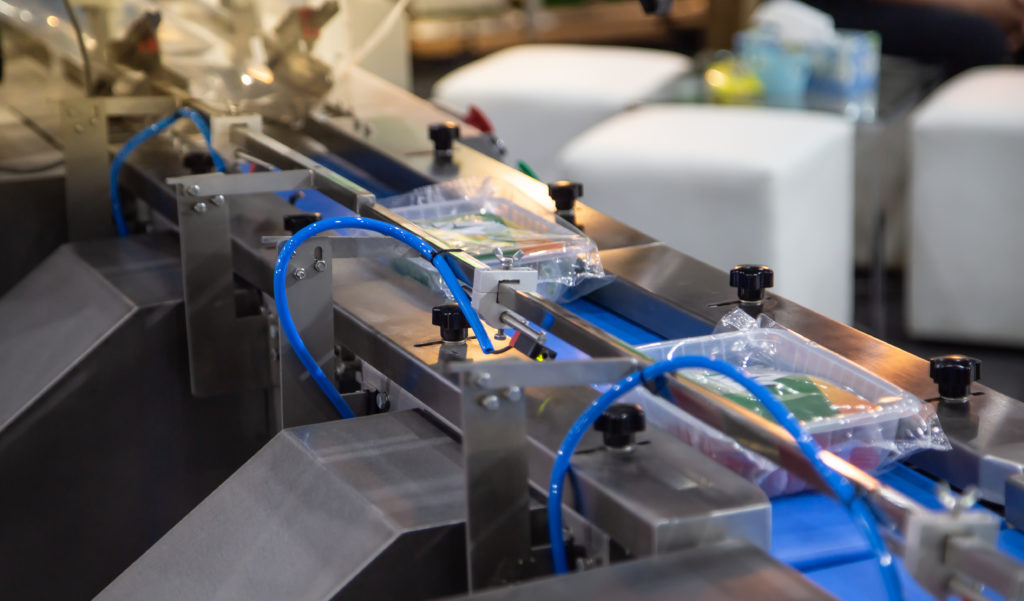

PETG is also utilized heavily in product packing and conveying applications. Like similar plastics, its relatively high resistance to temperatures and chemicals makes it a perfect choice where the product may undergo certain conditions or treatments in the production line. Because of these attributes and benefits, this material is highly useful in autonomous manufacturing and commercial facilities.

Polymershapes is your leading supplier of PETG and plastic materials. If you need a fast quote on product availability, quick shipping, and a large inventory of locally-available materials, give us a call today. We’ll make sure your project is handled with precision, speed, and care. We have the experience, quality process, and distribution capabilities to ensure your project is successful.