Plastic Products for Chemical Applications

Products for Compliance, Resistance, & Purity

About Chemical Industry Plastics

Chemicals can eat through many traditional materials, but not corrosion-resistant plastics. The right plastic can ensure safe, durable, long-lasting performance even under the harshest conditions. It can cut costs, reduce weight, and decrease maintenance by extending part life. Materials used in the chemical industry must typically meet very specific performance requirements. Semi-crystalline materials that perform in conditions rated as “engineering” or “advanced engineering” are usually specified. Resistance to chemicals, corrosion, and heat are a must.

Polypropylene (PP) is widely regarded as one of the safest plastics available for use in the chemical industry. This semi-crystalline, commodity-grade, FDA-compliant plastic is hailed for its good chemical resistance, low moisture absorption, and high resistance to cracking.

Ultra-high Molecular Weight Plastics for High-Temperature and Corrosive Materials

For more demanding or higher-temperature applications, ultra-high molecular weight polyethylene (UHMW-PE) is a semi-crystalline standard plastic with higher overall strength, even better chemical and corrosion resistance, and increased wear resistance. For critical applications such as tank linings that require the highest levels of purity and chemical resistance and outstanding mechanical properties, polyvinylidene fluoride (PVDF) is often the solution of choice.

Polymershapes Provides Industry Proven Brand Name Plastics for Any Chemical Application

Polymershapes is a leading distributor of the highest quality plastic material for chemical applications. We work with the industry’s most proven brands and manufacturers such as SIMONA and Mitsubishi Chemical Group to ensure lasting quality in every application. Harsh chemical environments need materials with high chemical and corrosion resistance and reliable tensile strength. Whether you’re looking to invest in laboratory countertop materials, chemical piping systems, or anti-stress/cracking material, Polymershapes has the solution to every need. Contact us today to speak with a material expert.

Polymershapes Provides Industry Proven Brand Name Plastics for Any Chemical Application

Polymershapes is a leading distributor of the highest quality plastic material for chemical applications. We work with the industry’s most proven brands and manufacturers such as SIMONA and Mitsubishi Chemical Group to ensure lasting quality in every application. Harsh chemical environments need materials with high chemical and corrosion resistance and reliable tensile strength. Whether you’re looking to invest in laboratory countertop materials, chemical piping systems, or anti-stress/cracking material, Polymershapes has the solution to every need. Contact us today to speak with a material expert.

Features & Benefits

Corrosion Resistant

•High Purity Materials

•Wide Range of Temperatures

•Flame Rated

•Regulatory Compliant

•Low Friction

•Static Dissipative Options

•High Strength-to-Weight Ratio

•Pressure & Burst Resistant

•Fatigue Resistant

•Lightweight

•Easily Machined

•Color Variety

Corrosion Resistant

Performs in corrosive environments and resists chemical degradation.

High Purity Materials

Reduces contamination and outgassing in sensitive processes.

Wide Range of Temperatures

Functions across broad thermal conditions.

Flame Rated

Meets flammability standards for safety compliance.

Regulatory Compliant

Available in FDA, USDA, and USP Class VI grades.

Low Friction

Promotes smooth fluid flow.

Static Dissipative Options

Protects equipment by reducing electrostatic buildup.

High Strength-to-Weight Ratio

Provides durable performance without excessive weight.

Pressure & Burst Resistant

Withstands high pressures without rupturing.

Fatigue Resistant

Maintains performance under repeated mechanical stress.

Lightweight

Improved efficiency and ease of installation.

Easily Machined

Can be formed, welded, or cut to fit.

Color Variety

Available in multiple colors to identify contents or systems.

Applications

Chemical Containers for Storage or Retention

Containers used for chemical storage or retention must be able to withstand long-term exposure without breaking down or contaminating the contents. High density polyethylene (HDPE) has the chemical resistance, durability, and corrosion resistance to withstand a broad range of acids and bases. For certain chemicals, ultra-molecular weight polyethylene (UHMW-PE) such as TIVAR® 1000 provides additional chemical resistance, even under higher temperatures.

Drain-waste-vent Systems

Drain-waste-vent systems capture sewage and greywater and transport them toward a water treatment system. This combination of pipes and plumbing fixtures must promote ease of flow and be able to withstand constant exposure to water and chemicals such as soaps and detergents. Polyvinyl chloride (PVC) is commonly used in plumbing systems and is readily available in pipe form.

Fume Hoods & Ducting

Fume hoods capture potentially dangerous gases or vapors and remove them from a laboratory setting. SIMONA PP-H 520 White polypropylene provides a sleek white appearance to this crucial ventilation system without cracking or absorbing any of the chemicals it comes in contact with.

Gaskets, Seals & Spacers

While acetal or nylon are good choices for many standard-use seals, the chemical industry often requires higher-performance materials for its gasket and spacer applications. Polytetrafluoroethylene (PTFE) is a very pure, non-stick material that is often used to protect the purity of substances. It features excellent chemical resistance even up to 450˚F.

HPLC Tubing & Valve Components

High Performance Liquid Chromatography, or HPLC, separates components of a mixture so they can be analyzed. This sophisticated process utilizes high pressure and a variety of solvents.

Polyetheretherketone (PEEK) is the preferred material for HPLC tubing and valve components because it remains durable and reliable even at high pressures. This high-performance plastic retains its purity and chemical resistance even under extremely harsh conditions.

Laboratory Countertops or Other Processing Areas

Polypropylene (PP) is the most common plastic used for laboratory countertops and chemical processing areas because it balances economy with solid chemical resistance, low moisture absorption, and high resistance to cracking. SIMONA® homopolymer polypropylene (PP-H) not only offers standard FDA-compliance, but is USP Class VI approved as well for medical environments.

Piping

PVC is well known for its use in many piping applications, pairing corrosion and chemical resistance and ease of flow with cost-efficiency. HDPE piping is gaining prominence and is an excellent choice when you need improved chemical resistance or enhanced durability.

Safety Barriers

Most chemicals can damage human skin, making safety barriers such as eye or face shields essential protective equipment in any lab environment. It’s important that these see-through shields don’t obstruct the wearer’s vision while protecting them from chemical splashes. LEXAN™ 9034 polycarbonate (PC) offers optical clarity and chemical resistance while also being virtually shatterproof.

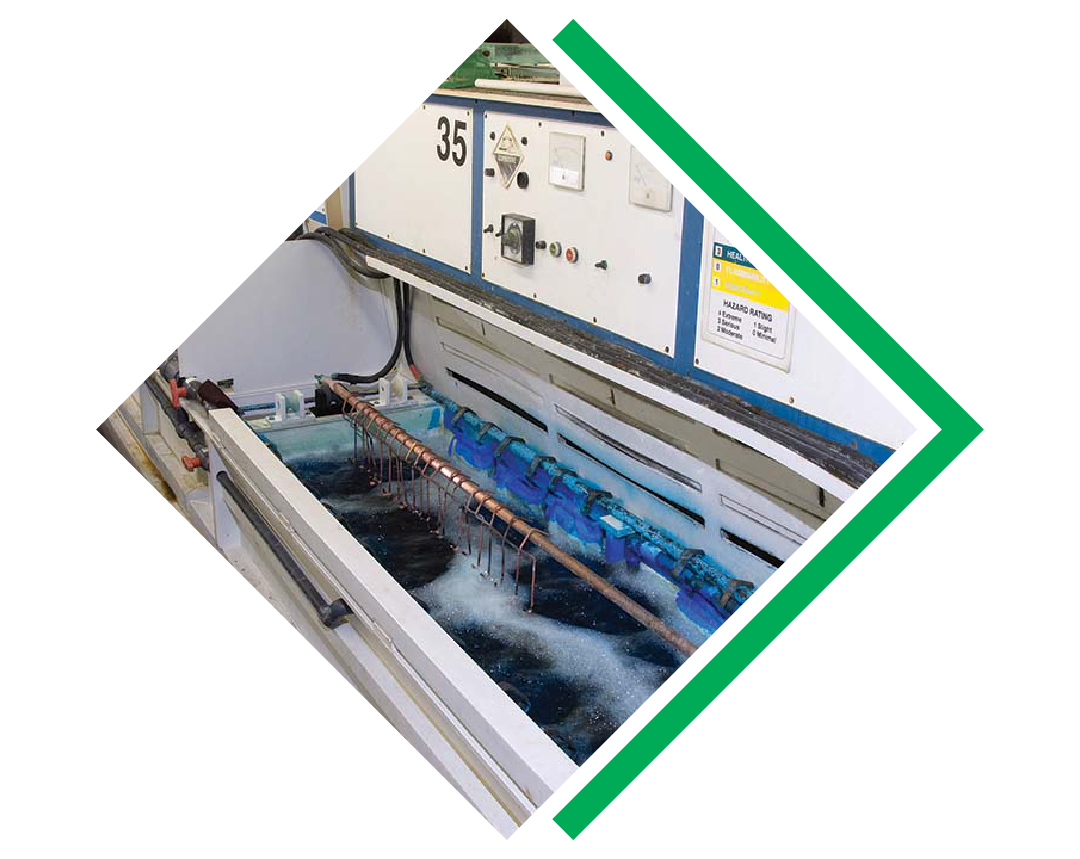

Tank & Tank Liners

Tank manufacturing requires durable, chemical resistant materials capable of containing anything from harsh chemicals to fuel to water. Tanks may be used to store or transport chemicals. Plating tanks are used for electroplating, etching, pickling, or other chemical processes. Performance plastics offer lightweight, cost-effective solutions that are corrosion and chemical resistant to prevent contamination of the tank’s contents. Polyvinyl chloride (PVC) is a low-cost material often used for tank liners because it’s non-flammable and can insulate the chemicals being transported. Copolymer polypropylene (PP-C) provides increased impact strength at low temperatures and superior resistance to stress cracking. For the harshest of chemicals, polyvinylidene fluoride (PVDF) such as KYNAR® 740 offers the best performance and highest purity, even at high temperatures.

Wall Linings & Cladding

Plastic offers a range of solutions for wall cladding and linings for cleanrooms and chemical processing areas. A wall lining material should be resistant to whatever chemicals it may encounter, easy to clean, and present a professional appearance. SIMONA PP-H 520 White polypropylene is a common choice for cleanrooms because of its chemical resistance and bright white appearance. PVC offers a cost-effective solution for wall cladding, while UHMW-PE provides increased chemical resistance for wall linings. For the harshest environments or strongest chemicals, PTFE offers superior performance.

Other Applications

- Barrels

- Fuel transportation and holding systems

- Laboratory equipment

- Paper bleaching

- Pharmaceutical research

- Pulp bleaching

- Pump and valve components

- Renal care facilities

Products for Chemical Applications

Composites & Processing Aids

Polymershapes can support your processing aid needs from several major manufacturers, these products include but are not limited to vacuum bag films; release films, liquids, and fabrics; adhesive and sealant tapes; autoclave valves and hoses; castable urethane elastomer; tooling resins, and tool support structures.

ECTFE (Ethylene Chlorotrifluoroethylene)

ECTFE (ethylene chlorotrifluoroethylene) offers an excellent combination of properties for chemical and elevated temperature applications. Often used in the semiconductor industry, and cleanroom equipment, ECTFE is corrosion and chemical resistant, with flame resistant properties.

Industrial PVC/CPVC

PVC is an amorphous thermoplastic material, with a range of continuous use temperatures varying by type (Type I, Type II or CPVC).

PPS (Polyphenylene Sulfide)

PPS (Polyphenylene Sulfide) is a tough, high-performance engineering thermoplastic featuring high dimensional stability.

PTFE (Polytetrafluoroethylene)

Polytetrafluoroethylene (PTFE) is a high molecular weight polymer with excellent thermal and electrical insulation properties, and a low coefficient of friction. It is a highly versatile plastic material useful in a broad range of high technology market segments and products, and its properties can be modified by additives such as glass fiber, carbon, or graphite.

PVDF (Polyvinylidene Fluoride)

PVDF (polyvinylidene fluoride), sometimes known by the tradename Kynar®, is an engineering thermoplastic offering high purity, excellent chemical resistance, flame resistance, and abrasion resistance. Easy to weld, PVDF is often seen semiconductor equipment, tank liners, and various seals, fittings, valves, and pump parts.

Have a Project? Get in Touch Today!

Our materials experts will help identify the right solution for your application, put together a quote and a detailed timeline.

Stay Informed with Our Newsletter

Be the first to see our latest promotions, new materials and valuable informative content by signing up for our newsletter.