Plastic Products for Medical Applications

Products for Purity, Compliance, & Precision

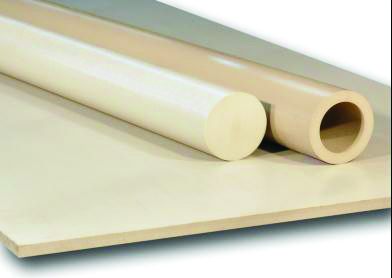

About Medical Industry Plastics

The medical industry places stringent demands on material quality, purity, and product documentation. It’s also constantly seeking cost-savings, such as long-lasting materials that can be used in less invasive treatments. Medical-grade performance plastics are just what the doctor ordered in many demanding life science applications. Often replacing metals or ceramics, plastics can offer biocompatibility, chemical resistance, sterilization capabilities, and lot traceability while also being lightweight, easy and cost-effective to fabricate, and available in a range of colors for design flexibility and implant trialing. Antimicrobial plastics can even help reduce contamination, while see-through plastics can provide protection to health care providers from pathogens like COVID-19.

For a plastic to qualify as medical grade, it must be safe to use in, on, or around patients and pose no major health risks within its application. There are many regulations detailing what makes a material safe for various life sciences applications. ISO 10993 regulates the health and safety standards for medical devices. Whether a device is active or inactive, implantable or non-implantable, these standards seek to ensure that the plastic within the device is not a health risk to the user. Materials in patient-contact applications must not react with organic tissue or trigger adverse side effects. The FDA outlines in-depth regulations that dictate which materials can be used around food and organic material. In the medical field, this is important for devices that are ingested. The BioPhorum Operations Group has standards to minimize leaching risk for single-use items, which are frequently referenced by the industry. USP Class VI outlines health and safety standards for components in medical devices. When plastics are used as pharmaceutical tubing, fabricated parts, or fittings, it’s important to ensure no dangerous reactions with the patient or other components will occur during use.

Materials Created to Endure Heavy Sanitation Requirements

One of the most important aspects of the medical industry is maintaining a safe and sterile environment. Medical professionals come in regular contact with bacteria, pathogens, diseases, and bodily fluids. To protect themselves and their patients, medical devices undergo rigorous sterilization techniques, such as gamma radiation or ethylene oxide sterilization. Materials must be able to endure regular sterilization without being damaged or compromising performance. The medical field also utilizes a diverse array of powerful chemicals and substances, both for sterilization and treatment. Medical-grade plastics offer excellent chemical resistance, and many can be steam autoclaved.

Polymershapes Carries the Safest Medical Grade Plastics in the Idustry

Polymershapes works with industry-leading manufacturers that develop and process the highest-quality medical-grade plastics available, offering lot and batch traceability and the highest of purity standards. The biocompatible materials we offer feature anti-leaching properties and low absorption, leading to a more controllable working environment, and are often chemically inert and free of animal byproducts. No matter the application, Polymershapes has medical-grade plastic solutions that support long-term safety and reliability. We offer a broad portfolio of virgin-grade, biocompatible polymers, along with a growing portfolio of high-performance recycled engineering plastics. Contact us today to discuss our medical and life science polymers.

Polymershapes Carries the Safest Medical Grade Plastics in the Idustry

Polymershapes works with industry-leading manufacturers that develop and process the highest-quality medical-grade plastics available, offering lot and batch traceability and the highest of purity standards. The biocompatible materials we offer feature anti-leaching properties and low absorption, leading to a more controllable working environment, and are often chemically inert and free of animal byproducts. No matter the application, Polymershapes has medical-grade plastic solutions that support long-term safety and reliability. We offer a broad portfolio of virgin-grade, biocompatible polymers, along with a growing portfolio of high-performance recycled engineering plastics. Contact us today to discuss our medical and life science polymers.

Features & Benefits

Regulation Compliant

•Biocompatibility

•Lot Traceability

•Sterilization Resistant

•Chemical Resistant

•Wide Temperature Range

•Color Variety

•Low Manufacturing Costs

•Lightweight & Impact Resistant

•Noise Reduction

•Antimicrobial

•Comfortable to Touch

Regulation Compliant

Meets ISO 10993, FDA, BPOG, ADI-Free, and USP Class VI standards.

Biocompatibility

Safe for use with human tissue and bodily fluids.

Lot Traceability

Ensures traceability to raw materials for purity and compliance.

Sterilization Resistant

Tolerates repeated steam or chemical sterilization.

Chemical Resistant

Compatible with harsh cleaning agents and disinfectants.

Wide Temperature Range

Reliable performance across extreme temperatures.

Color Variety

Available in various colors for device coding or identification.

Low Manufacturing Costs

Easy to machine and cost-effective to produce.

Lightweight & Impact Resistant

Combines durability with ease of handling.

Noise Reduction

Quieter than metal parts and self-lubricating.

Antimicrobial

Prevents microbial contamination on medical surfaces.

Comfortable to Touch

Ideal for handheld instruments and patient-facing surfaces.

Applications

Blood Reservoirs & Pumps

Polyetheretherketone (PEEK) is a high-performance material known for its extreme chemical resistance and strength, even at high temperatures. It is often used in blood pumps and reservoirs because it won’t react to or contaminate the blood.

Cabinets

High Density Polyethylene (HDPE) is a fantastic material for medical cabinets, shelves, and partitions due to its chemical and corrosion resistance, low moisture absorption, and high strength. It’s also extremely durable and capable of enduring constant use.

Caddies

Surgical caddies are used to store and move surgical instruments, so they must be easy to sterilize. Medical-grade plastic is an excellent material solution, as it’s lightweight for easy transport and compartments can be labeled by laser cutting or screen printing. While many polymers can be used, PPSU features improved impact strength and thermal stability over its PSU cousin, making it the perfect fit for ultimate performance.

Cleanrooms

Cleanrooms are controlled environments that filter out dust and airborne particles to provide a “clean,” uncontaminated space for sensitive medical equipment or pharmaceutical development. Polyvinyl chloride (PVC) and polypropylene (PP) are often used in cleanroom wall panels because they are easy to fabricate, install, and clean with solid chemical resistance. Medical-grade PP carries USP Class VI compliance and can even be autoclaved.

Cryogenics

While many applications deal with exceedingly high temperatures, cryogenics requires materials that perform in extremely low temperatures. Polychlorotrifluoroethylene (PCTFE) is unique in its ability to handle operating temperatures as low as -400°F.

Diagnostics & Lab Testing

ETFE tubing’s ability to reduce contamination risks and protect samples makes it a go-to for lab testing and diagnostics, especially when transferring samples from one container to another.

Dialysis Containers & Equipment

Dialysis containers and equipment both need to be made of biocompatible, high-performance materials that can be sterilized regularly. PEEK is often the ideal match for dialysis equipment due to its excellent performance properties.

Endoscopic Devices & Housing

Endoscopic devices are designed to come in close contact with organic tissue without reacting to the patient. Polysulfone (PSU), such as Solvay’s Udel® or Mitsubishi Chemical Group’s Sultron™, is a semi-transparent material known for its mechanical capabilities, paired with strong thermal and chemical tolerances. Its hydrolytic stability and high chemical resistance make it a common material for endoscopic control body housings.

Equipment Handles & Components

Equipment handles throughout the healthcare, medical, dental, and life sciences industries are designed for constant use and regular exposure to organic substances. Both PSU and PEI are proven materials, capable of enduring constant use, routine sterilization, and regular exposure to foreign materials. PSU is commonly used for handles, while PEI’s high strength makes it better suited for equipment components.

Face Shields

Face shields provide eye protection for medical professionals without sacrificing optical clarity. LEXAN™ polycarbonate is easy to clean and disinfect while offering high strength and an anti-fog coating.

Filtration & Fermentation Systems

Filtration and fermentation need materials that are strong enough to protect sensitive material while also allowing it to filter or ferment as needed. ETFE offers an excellent combination of chemical resistance, abrasion resistance, and flexibility, which help these systems operate at peak efficiency.

Hemodialysis Membranes

During kidney dialysis, a semi-permeable membrane removes toxins from a patient’s blood. PSU such as Solvay’s Udel is slightly porous, which makes cleansing and purifying organic fluid simpler and more effective.

Medical Machine Components

Medical machine components come with a long list of needs. On top of being biocompatible, they must be able to handle extreme conditions, constant use, and frequent sterilization. Polyetherimide (PEI), such as ULTEM™, is considered one of the strongest materials available. Its strength and durability, along with its flame and gamma radiation capabilities, allow it to handle routine abuse for long periods of time.

Medical Tubing

Medical tubing needs to be lightweight, durable, chemical-resistant, and abrasion-resistant to maintain purity and safety. Ethylene tetrafluoroethylene (ETFE) is a soft, flexible plastic frequently used for medical tubing. With operating temperatures of up to 300°F, it is strong enough to safely transfer various fluids across an array of conditions. At even higher temperatures, polytetrafluoroethylene (PTFE) may be utilized.

Orthopedic Implants & Trials

Orthopedics is a growing market driven by constant advancement. Implants, such as knee and hip replacements, must be made from biocompatible, chemically inert materials that can permanently operate inside the patient while coexisting with organic tissue. PEEK, such as Mitsubishi Chemical Group’s Ketron® or Westlake’s AROLUX™, has ultra-high strength with very low absorption, which makes it the perfect material for orthopedic implants. Polyphenylsulfone (PPSU) is commonly used for orthopedic trials as it is biocompatible and comes in a range of colors. Each standard implant size is typically fabricated in a different color. These colored trial implants are then used to determine the correct size needed for a patient’s permanent implant.

Packaging Material

PCTFE comes loaded with an array of protective features that help retain sample purity, especially when samples are moved from one place to another. Its chemical resistance ensures it won’t react to the samples, while its low-flammability and near-zero absorption protect it from outside contaminants.

Single-use Filtration, Peripherals, & Containment

PPSU features very high chemical resistance and heat capabilities, which make it useful for an array of long-term applications. However, it is also 100% recyclable, which makes it an excellent, sustainable option for single use needs as well.

Steam Cleaning Equipment

Autoclaving is one of the most common and demanding sterilization methods, where hot steam is used to cleanse medical devices and remove impurities. The cleaning equipment itself must also be able to withstand these high temperatures and harsh conditions. PSU’s hydrolytic properties make it an excellent, non-reactive material for steam cleaning equipment.

Steam & Gas Transfers

Transferring vapors and gases can be exceptionally challenging, especially when high temperatures and strict purity standards are involved. Doing so in a controlled fashion can be even more challenging. PTFE is proven to be reliable for steam and gas transfers, especially in harsher conditions where other tube materials may deteriorate.

Sterilization & Surgical Trays

In the medical and life sciences sector, particularly for sterilization and surgical tray applications, high-performance plastics play a critical role. Materials such as PPSU, PEEK, and other medical-grade polymers are selected because they can withstand rigorous sterilization processes, including steam autoclaving, gamma irradiation, and ethylene oxide gas, without degrading in performance, changing shape, or leaching harmful substances. These materials also offer excellent chemical resistance, temperature stability, lot and batch traceability, and biocompatibility. These qualities make them ideal for use in surgical trays, instrument caddies, sterilized kit trays, and packaging that must maintain a sterile barrier until use.

Surgical Packaging Material

PCTFE’s performance properties, low flammability, and near-zero absorption make it an ideal material for many surgical packaging needs.

Tank Liners

Polyvinylidene fluoride (PVDF)’s chemical resistance, abrasion resistance, UV stability, and very high purity make it a useful material for high-purity tank liners. Flame and abrasion resistance allow for a safe and more controllable working environment, while its chemical resistance and high purity help protect tank contents against contamination.

Ultrapure Liquid Transfer

Ultrapure liquid transfer demands materials that will not contaminate the purity of the liquid. Fluorinated ethylene propylene (FEP) is a tough, flexible plastic known for its extremely wide temperature range. Being chemically inert, it can be used to preserve the purity of various materials. Perfluoroalkox (PFA) is used when even higher temperatures are reached. Platinum-cored silicone is also available for the greatest purity needs. It contains no peroxide by-products and has very low extractables. Featuring low spallation and a very long pump life, it can ensure precise measurements while protecting purity.

Vaccine Manufacturing

Vaccines require highly controlled conditions to be effectively tested and administered. ETFE’s chemical resistance and wide temperature range make it usable across an array of environments, making vaccine testing, storage, and administration safe and effective.

Products for Medical Life Sciences Applications

APET (Amorphous Polyethylene Terephthalate)

APET (Amorphous-Polyethylene Terephathalate) film is known for its glossy, clear appearance. Offering crystal clear transparency, along with excellent chemical resistance, APET film is a popular choice for medical facesheilds.

PEEK (Polyetheretherketone)

PEEK (Polyetheretherketone) is a unique engineering thermoplastic offering high temperature resistance, toughness, rigidity, and creep resistance. It is resistant to a wide range of solvents, making it an excellent material for use in a wide spectrum of applications where thermal, chemical and combustion properties are critical to performance.

PETG (Polyethylene Terephthalate Glycol)

Polyethylene Terephthalate Glycol, or PETG, is a clear thermoplastic that can be formed into a number of shapes, making it suitable for use in a broad range of applications.

PPSU (Polyphenylsulfone)

PPSU (Polyphenylsulfone) is an amorphous thermoplastic material, with a continuous use temperature range of up to 300° F (149° C).

Have a Project? Get in Touch Today!

Our materials experts will help identify the right solution for your application, put together a quote and a detailed timeline.

Stay Informed with Our Newsletter

Be the first to see our latest promotions, new materials and valuable informative content by signing up for our newsletter.