Plastic Products for Semiconductor Applications

Products for Purity, Precision, & Control

About Semiconductor Industry Plastics

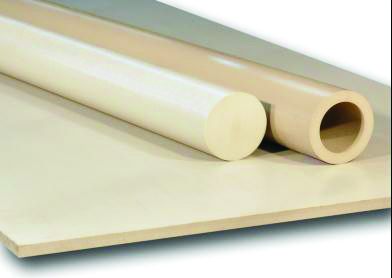

A wide variety of engineered plastics are used in the manufacturing of semiconductors, which are also known as microchips. Semiconductor manufacturing requires extreme precision and stability to prevent costly part failure. Because semiconductors are crucial components in everything from computers and mobile devices to vehicles to household appliances, it’s imperative to choose the right materials that can deliver safe and reliable performance at every stage of production.

Plastics Suited to Strict Quality Control Guidelines

Since semiconductors control the flow of currents, the industry demands materials that can handle the heat and maintain control over electrical charges. Many plastics are resistant to the corrosive acids and harsh chemicals used in the chip making process. Performance plastics can also deliver a wealth of other advantages including weight reduction, electrical insulating properties, high purity, flame-retardant properties, and cost-effectiveness. Low-outgassing and static dissipative grades are available to help reduce potential interference, enhancing the functionality of electronic equipment.

Polymershapes Carries A Wide Variety of Materials for Any Project

Because of these diverse needs, performance plastics used in the semiconductor industry can span the entire plastics pyramid, including amorphous and semicrystalline plastics, thermoplastics and thermosets, and even imidized materials. Products near the base of the pyramid such as polypropylene and PVC are often used in applications with direct exposure to chemicals, while high performance advanced materials such as PEEK are trusted to come into contact with the microchips themselves during manufacture or testing.

Polymershapes Carries A Wide Variety of Materials for Any Project

Because of these diverse needs, performance plastics used in the semiconductor industry can span the entire plastics pyramid, including amorphous and semicrystalline plastics, thermoplastics and thermosets, and even imidized materials. Products near the base of the pyramid such as polypropylene and PVC are often used in applications with direct exposure to chemicals, while high performance advanced materials such as PEEK are trusted to come into contact with the microchips themselves during manufacture or testing.

Leading Provider of Semiconducter Plastic Materials

Polymershapes is North America’s leading provider of semiconductor plastics, with an extensive inventory and over 80 years of experience providing material solutions by world-class manufacturers such as Mitsubishi Chemical Group, Plaskolite, and SIMONA. If you’re looking for the right high-performance plastic for a semiconductor application, our experts can help you determine exactly which material and grade is best for you to improve safety, stability, and performance.

Features & Benefits

Chemical & Corrosion Resistance

•Nonflammable

•Low Outgassing

•Static Dissipative & Electrically Insulated

•Abrasion Resistant

•High Purity Materials

•Lightweight

Chemical & Corrosion Resistant

Withstands harsh process chemicals and acids.

Nonflammable

Performs at high temperatures with no ignition risk.

Low Outgassing

Prevents contamination in cleanroom environments.

Static Dissipative & Electrically Insulated

Materials available for both ESD protection and insulation.

Abrasion Resistant

Withstands slurry contact in polishing and etching.

High Purity Materials

Maintains process integrity and prevents contamination.

Lightweight

Lightweight for ease of use and improved efficiency.

Applications

Chemical Tanks

Plastics are a great choice for light weight chemical tanks and liners due to their chemical, corrosion, and impact resistance and ease of fabrication. Depending on the specific chemicals being stored and the temperature range encountered, high density polyethylene (HDPE), polypropylene (PP), and polyvinyl chloride (PVC) are often cost-effective options. When an application calls for the highest purity, investing in polyvinylidene fluoride (PVDF) provides long-lasting chemical, abrasion, and flame resistance even at high temperatures.

Electrical Insulators

Many plastics make excellent electrical insulators. To choose the right one for your application, it’s important to know the temperatures and chemicals the insulator may encounter. Acetal is commonly chosen for its low moisture absorption, strength, and dimensional stability. Polypropylene (PP) offers excellent chemical resistance and excels in harsh environments. In the most extreme and demanding environments, polyetherimide (PEI) offers outstanding dimensional stability and chemical resistance even at very high temperatures.

Flexible Tubing

PVC is well known for its use in a variety of tubing applications. Chlorinated polyvinyl chloride (CPVC) offers the same great chemical and fire resistance with additional temperature resistance. When high purity is critical, perfluoroalkoxy (PFA) tubing is often preferred.

High-Purity Piping Systems

For high and ultra-high purity applications, PVDF is the material of choice. This versatile high-performance plastic is also known for its temperature, chemical, UV, and abrasion resistances.

Semicon Trays & Boxes

Because semicon wafers are so precious, they are stored and transported in specially designed carrier boxes. Natural colored or black polypropylene (PP) with ESD properties is often selected because of its high strength and impact resistance, low weight, ease of fabrication, and excellent chemical and temperature resistance.

Test Sockets

After manufacturing, microchips are connected to test sockets and subjected to rigorous assessments to ensure they are working correctly. Polyetheretherketone (PEEK) is the material of choice because its excellent dimensional stability allows precise machining, and its wide operating temperature range allows it to retain that stability even up to 480˚F. With low moisture absorption, low outgassing, and a V-0 flammability rating, PEEK can withstand the conditions of the harshest tests.

Valves & Fittings

Polycarbonate (PC) is commonly used for valves, fittings, and similar applications throughout the semiconductor industry because it combines strength and versatility with excellent shock resistance. While its physical properties can withstand demanding conditions and high temperatures, it’s also thermoformable and easy to machine. If you need a stronger insulator, polytetrafluoroethylene (PTFE) offers extremely low conductivity.

Wafer Handling Parts

Hundreds of microchips are made from a single semiconductor wafer. Any failure in this sensitive process can result in an extremely expensive loss. Only the most reliable materials can be trusted to be in contact with the wafers. PEEK is strong, dimensionally stable, and able to withstand contact with harsh chemicals and very high temperatures.

Wet Benches & Workstations

Wet benches are workstations used for chemical processing, which is a key component of semiconductor manufacturing. The materials used must be able to withstand repeated exposure to harsh chemicals. PVC and polypropylene commonly make up the bulk of this equipment. Both offer excellent chemical resistance and are easy to thermoform or fabricate.

Products for Semiconductor Applications

ECTFE (Ethylene Chlorotrifluoroethylene)

ECTFE (ethylene chlorotrifluoroethylene) offers an excellent combination of properties for chemical and elevated temperature applications. Often used in the semiconductor industry, and cleanroom equipment, ECTFE is corrosion and chemical resistant, with flame resistant properties.

PAI (Polyamide-imide)

PAI (Polyamide-imide) is an imidized thermoplastic material, with a continuous use temperature range of up to 500° F (260° C).

PBI (Polybenzimidazole)

PBI (polybenzimidazole) such as Duratron® from Mitsubishi Chemical Advanced Materials, features the highest mechanical properties of any plastic above 400°F as well as the lowest coefficient of thermal expansion and highest compressive strength of all unfilled plastics.

PEEK (Polyetheretherketone)

PEEK (Polyetheretherketone) is a unique engineering thermoplastic offering high temperature resistance, toughness, rigidity, and creep resistance. It is resistant to a wide range of solvents, making it an excellent material for use in a wide spectrum of applications where thermal, chemical and combustion properties are critical to performance.

PTFE (Polytetrafluoroethylene)

Polytetrafluoroethylene (PTFE) is a high molecular weight polymer with excellent thermal and electrical insulation properties, and a low coefficient of friction. It is a highly versatile plastic material useful in a broad range of high technology market segments and products, and its properties can be modified by additives such as glass fiber, carbon, or graphite.

Have a Project? Get in Touch Today!

Our materials experts will help identify the right solution for your application, put together a quote and a detailed timeline.

Stay Informed with Our Newsletter

Be the first to see our latest promotions, new materials and valuable informative content by signing up for our newsletter.