ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene) is an amorphous thermoplastic material, with a continuous use temperature range of -4° F (-20° C) to 176° F (80° C). It is categorized as a standard material, and offers a balanced combination of mechanical toughness, impact resistance, and ease of fabrication and thermoforming.

ABS/PVC

ABS/PVC blend sheet, such as Boltaron, offers some of the best aspects of these two common thermoplastics. Excellent for thermoforming applications, it maintains high consistency from lot to lot fabricating, and uniformity in deep draws and sharp corners.

Acetal (Polyoxymethylene, POM)

Acetal, also known as POM (Polyoxymethylene), is a semi-crystalline engineering thermoplastic material, with a continuous use temperature range of up to 180° F (82° C). Acetal offers high strength and stiffness coupled with high dimensional stability and ease of machining.

Acrylic (Polymethyl Methacrylate, PMMA)

Acrylic, also known as Polymethyl Methacrylate (PMMA), is a thermoplastic that can be formed into a number of shapes, making it suitable for use in a broad range of industries and products.

Expanded Foam PVC

Expanded Foam PVC sheet is a versatile material, often used in the sign and graphics industry. Expanded closed-cell polyvinyl chloride (PVC) sheets are durable and rigid with a matte finish.

Foam Polypropylene (PP)

Foamed polypropylene sheets, such as PolyCraft®, are an excellent choice for signage and displays. Lightweight, and UV resistant, the material can be used outdoors without concerns of graphics fading.

High Density Polyethylene (HDPE)

HDPE (High Density Polyethylene), part of the polyolefin family of materials, is a semi-crystalline thermoplastic material, with a continuous use temperature range of -50° F (-46° C) to 180° F (82° C).

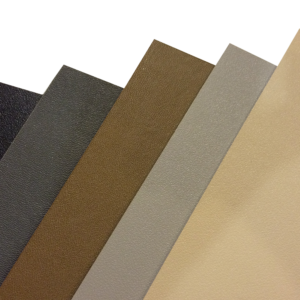

High Impact Polystyrene (HIPS)

HIPS (High Impact Polystyrene), also known as PS (Polystyrene), is an amorphous thermoplastic material, used in lower heat applications. It is categorized as a standard material, and offers ease of processing, high impact strength, and stiffness.

Industrial PVC/CPVC

PVC is an amorphous thermoplastic material, with a range of continuous use temperatures varying by type (Type I, Type II or CPVC).

Low Density Polyethylene (LDPE)

LDPE (Low Density Polyethylene), also known as a polyolefin material, is a semi-crystalline thermoplastic material, with a continuous use temperature range of up to 200° F (93° C).

Nylon (Polyamide, PA)

Nylon is one of the original engineering thermoplastic materials. With an ideal balance of strength and toughness it finds use in a wide variety of industries and applications.

PEEK (Polyetheretherketone)

PEEK (Polyetheretherketone) is a unique engineering thermoplastic offering high temperature resistance, toughness, rigidity, and creep resistance. It is resistant to a wide range of solvents, making it an excellent material for use in a wide spectrum of applications where thermal, chemical and combustion properties are critical to performance.

PEI (Polyetherimide, ULTEM™)

PEI (Polyetherimide) is an amorphous engineering thermoplastic offering exceptional mechanical, thermal and electrical properties. It can be easily machined with conventional metalworking tools, and can be painted, hot stamped, printed or metallized.

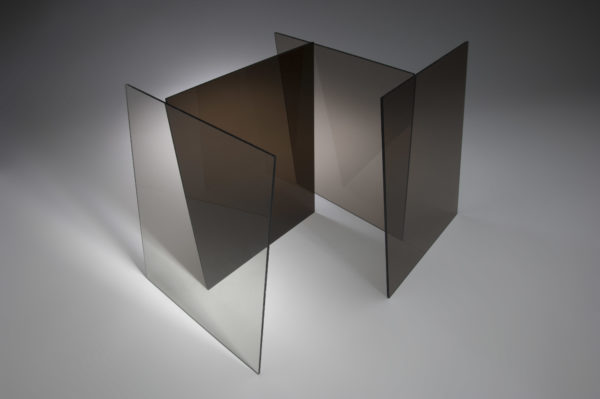

PETG (Polyethylene Terephthalate Glycol)

Polyethylene Terephthalate Glycol, or PETG, is a clear thermoplastic that can be formed into a number of shapes, making it suitable for use in a broad range of applications.

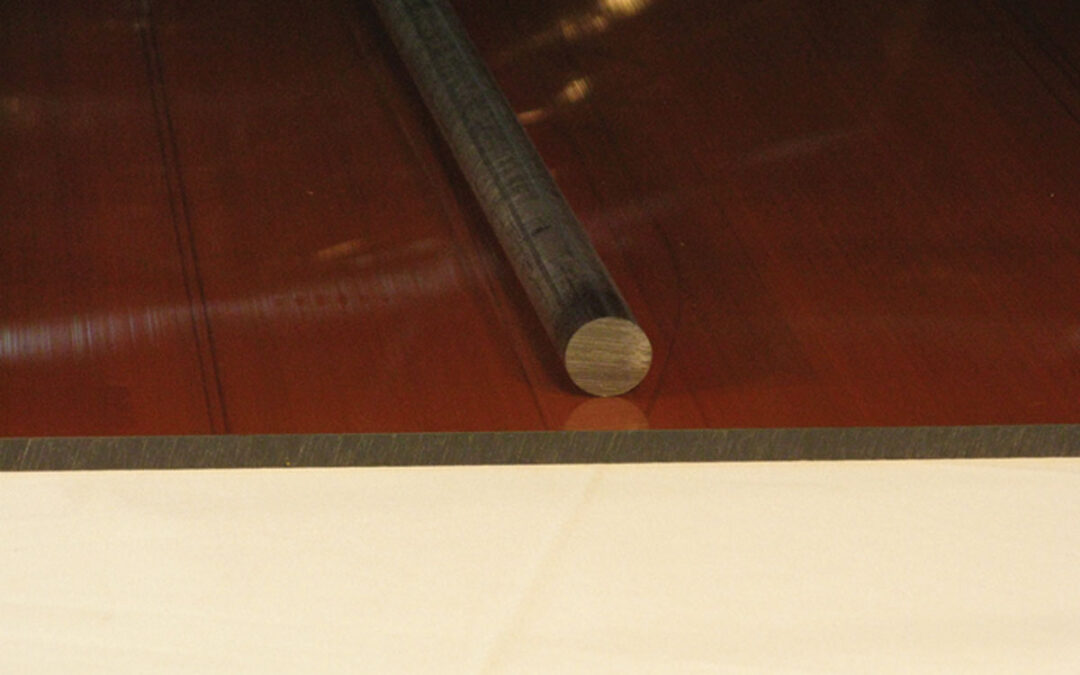

Phenolic/Thermoset Plastics

Phenolics, also known as Thermosets, are extremely versatile machinable plastics that deliver unique properties by combining resins with composite materials.

Polycarbonate

Polycarbonate, also referred to as PC, is a tough, impact-resistant, virtually unbreakable material used in wide variety of applications. It is an amorphous thermoplastic material, with a continuous use temperature range of up to 265° F (129° C).

Polyester (PET)

Polyethylene Terephthalate – known as PET or polyester — is a thermoplastic polyester that can be amorphous, crystalline, or a mixture of both, depending on how it is processed. All forms provide good chemical resistance and durability.

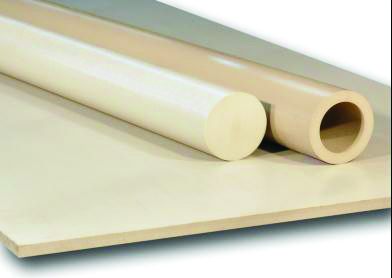

Polypropylene Sheet, Rod and Tube

Polypropylene (PP) is a semi-crystalline thermoplastic material, with a continuous use temperature range of -4° F (-20° C) to 212° F (100° C). It is categorized as a standard material, and offers excellent toughness, chemical resistance, and processability.

PPSU (Polyphenylsulfone)

PPSU (Polyphenylsulfone) is an amorphous thermoplastic material, with a continuous use temperature range of up to 300° F (149° C).

PVC-Acrylic

PVC-Acrylic is a thermoformable, high-impact, fire-rated sheet for a variety of aerospace and industrial applications.

PVDF (Polyvinylidene Fluoride)

PVDF (polyvinylidene fluoride), sometimes known by the tradename Kynar®, is an engineering thermoplastic offering high purity, excellent chemical resistance, flame resistance, and abrasion resistance. Easy to weld, PVDF is often seen semiconductor equipment, tank liners, and various seals, fittings, valves, and pump parts.

Ultra High Molecular Weight Polyethylene (UHMW)

UHMW, also known as UHMW-PE (Ultra High Molecular Weight Polyethylene), is a semi-crystalline thermoplastic material, with a continuous use temperature range of up to 180° F (82° C).