ABS (Acrylonitrile Butadiene Styrene)

ABS (Acrylonitrile Butadiene Styrene) is an amorphous thermoplastic material, with a continuous use temperature range of -4° F (-20° C) to 176° F (80° C). It is categorized as a standard material, and offers a balanced combination of mechanical toughness, impact resistance, and ease of fabrication and thermoforming.

High Density Polyethylene (HDPE)

HDPE (High Density Polyethylene), part of the polyolefin family of materials, is a semi-crystalline thermoplastic material, with a continuous use temperature range of -50° F (-46° C) to 180° F (82° C).

PEEK (Polyetheretherketone)

PEEK (Polyetheretherketone) is a unique engineering thermoplastic offering high temperature resistance, toughness, rigidity, and creep resistance. It is resistant to a wide range of solvents, making it an excellent material for use in a wide spectrum of applications where thermal, chemical and combustion properties are critical to performance.

PEI (Polyetherimide, ULTEM™)

PEI (Polyetherimide) is an amorphous engineering thermoplastic offering exceptional mechanical, thermal and electrical properties. It can be easily machined with conventional metalworking tools, and can be painted, hot stamped, printed or metallized.

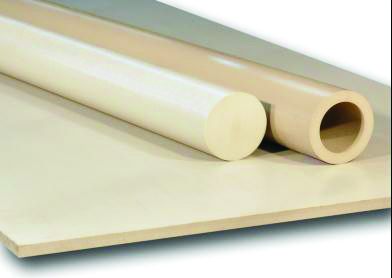

Polypropylene Sheet, Rod and Tube

Polypropylene (PP) is a semi-crystalline thermoplastic material, with a continuous use temperature range of -4° F (-20° C) to 212° F (100° C). It is categorized as a standard material, and offers excellent toughness, chemical resistance, and processability.

PPSU (Polyphenylsulfone)

PPSU (Polyphenylsulfone) is an amorphous thermoplastic material, with a continuous use temperature range of up to 300° F (149° C).

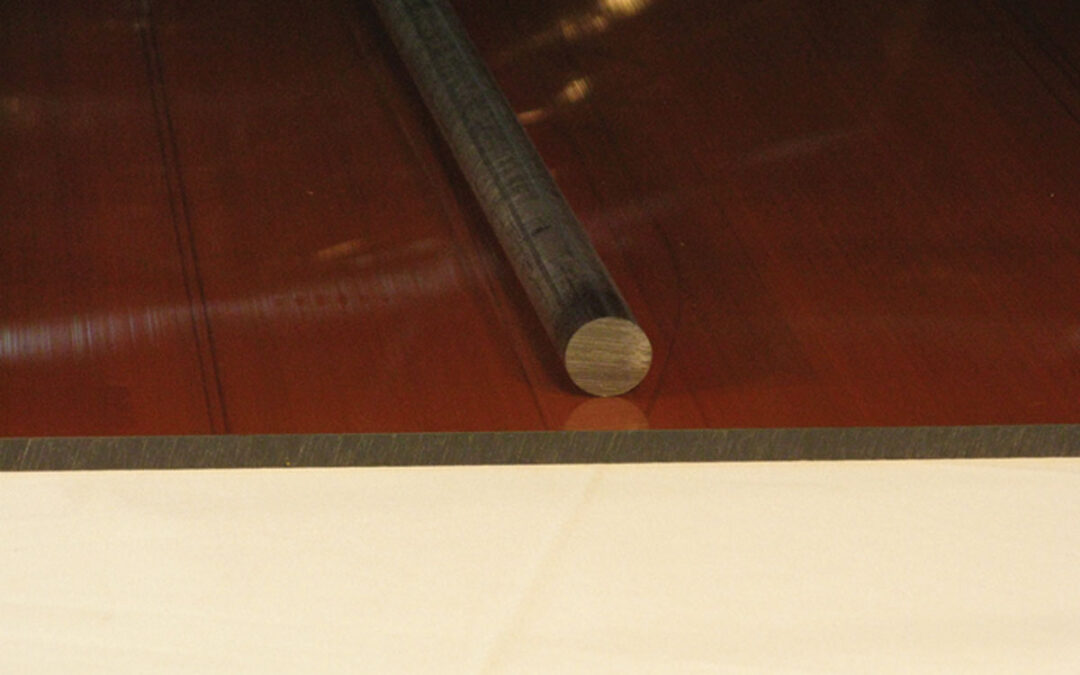

PTFE (Polytetrafluoroethylene)

Polytetrafluoroethylene (PTFE) is a high molecular weight polymer with excellent thermal and electrical insulation properties, and a low coefficient of friction. It is a highly versatile plastic material useful in a broad range of high technology market segments and products, and its properties can be modified by additives such as glass fiber, carbon, or graphite.

PVDF (Polyvinylidene Fluoride)

PVDF (polyvinylidene fluoride), sometimes known by the tradename Kynar®, is an engineering thermoplastic offering high purity, excellent chemical resistance, flame resistance, and abrasion resistance. Easy to weld, PVDF is often seen semiconductor equipment, tank liners, and various seals, fittings, valves, and pump parts.